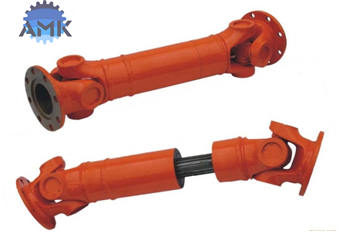

Universal Shaft Coupling

Universal Shaft Coupling Specification

- Drive Type

- Rotational Shaft Coupling

- Noise Level

- Low

- Usage & Applications

- Industrial machinery, Automotive, Power plants, Conveyor systems

- Surface Finish

- Smooth, Corrosion-resistant

- Features

- Flexible, Durable, Easy Installation, Shock Absorbing

- Size

- Standard sizes or as per client specification

- Lubricating System

- Requires periodic greasing

- Diameter

- 20 mm to 320 mm

- Capacity

- High Torque Transmission

- Shape

- Cylindrical / Flanged

- Product Type

- Universal Shaft Coupling

- Material

- Alloy Steel / Carbon Steel

- Technology

- Machined

- Power Source

- Mechanical

- Power

- Suitable for power transmission between shafts

- Surface Treatment

- Phosphated / Painted / Polished

- Dimension (L*W*H)

- Standard and customizable sizes available

- Weight

- Depends on size and material (generally 2-20 kg)

- Color

- Black, Grey Metallic Finish

- Corrosion Resistance

- Enhanced due to surface treatment

- Component Parts

- Yoke, cross & bearings, sleeve couplings

- Installation

- Flange and Bolt Mounting

- Maintenance

- Low, periodic lubrication required

- Max Operating Speed

- Up to 6000 RPM

- Alignment Tolerance

- High angular and radial misalignment compensation

- Connection Type

- Universal Joint (UJ) Type

- Packaging

- Wooden Box/Carton

- Temperature Range

- -20°C to 120°C

- Standard Compliances

- DIN, JIS, ASTM Standards

- Torque Range

- Customized as per application up to 50,000 Nm

- Application Industry

- Steel plants, cement, mining, fertilizer, power plants

Universal Shaft Coupling Trade Information

- Minimum Order Quantity

- 2 Pieces

- FOB Port

- Shanghai

- Payment Terms

- Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cash in Advance (CID)

- Supply Ability

- 100000 Pieces Per Month

- Delivery Time

- 45 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- South America, Middle East, Central America, Eastern Europe, Australia, Western Europe, Africa, Asia, North America

- Main Domestic Market

- All India

About Universal Shaft Coupling

Universal Shaft Coupling

Couplings

By cooperating with Chinese domestic leading manufacturers, were able to supply all kinds of couplings to meet your requirements.

The universal coupling shaft is used to connect driving shaft and driven shaft of two different mechanisms, so that torque could be transferred.

Universal Joint Shaft (Universal Coupling) is used as the main transmission connecting shaft for the main transmission of hot continuous rolling rough mill, large section steel rolling mill, punching machine, medium width plate mill, steckelmill and other heavy machinery.

Reliable High-Misalignment Compensation

The Universal Shaft Coupling effectively accommodates significant angular and radial misalignments, ensuring seamless power transmission even in systems with imperfect shaft alignment. Its universal joint design maintains performance and reduces the risk of equipment damage or downtime due to misalignment, making it a preferred choice in complex industrial settings.

Engineered for Extreme Operating Conditions

Built to operate from -20C to 120C and withstand high mechanical loads, this coupling is suitable for use in intense environments such as steel plants, cement mills, and mining sites. Advanced surface treatments, including phosphating and painting, provide robust corrosion resistance, while the machined technology guarantees a smooth, reliable finish and optimal function.

FAQs of Universal Shaft Coupling:

Q: How does the universal shaft coupling handle shaft misalignment?

A: The universal shaft coupling is specifically designed to accommodate high angular and radial misalignments between connected shafts. Its universal joint construction allows it to pivot and flex, maintaining consistent power transmission and reducing stress on connected equipment.Q: What industries commonly use this coupling, and why is it beneficial?

A: This coupling is widely used in steel plants, cement factories, mining operations, fertilizer production, power plants, and other heavy-duty industries. Its ability to transmit high torque, resist corrosion, and operate under harsh conditions makes it immensely beneficial for equipment reliability and longevity.Q: When is periodic maintenance or lubrication required for the coupling?

A: Although the universal shaft coupling is low-maintenance, periodic lubrication (typically greasing) is recommended according to the operating conditions and manufacturers guidelines. Regular lubrication ensures smooth operation and extends the lifespan of bearing and cross components.Q: Where can this coupling be installed and what mounting options are available?

A: It can be installed between any two rotational shafts requiring power transmission in industrial and automotive machinery. It features flange and bolt mounting, facilitating secure and straightforward attachment to different types of equipment.Q: What is the process for customizing the couplings dimensions or torque capacity?

A: Customized dimensions or torque requirements can be specified by the client during the ordering process. The manufacturer will then engineer the coupling using alloy or carbon steel and machinery processes that meet the required torque (up to 50,000 Nm) and exact dimensions.Q: What are the key benefits of using this universal joint type shaft coupling?

A: Key benefits include high angular and radial misalignment compensation, ease of installation, enhanced corrosion resistance, low noise, high torque transmission, and suitability for both standard and custom applications. This versatility and durability contribute directly to operational efficiency and equipment safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rolling Mill Machinery Parts Category

Rolling Mill Guide

Price 1000 USD ($) / Set

Minimum Order Quantity : 2 Sets

Technology : Other, Hot Rolling Mill Technology

Weight : Varies as per specification

Material : Highgrade Alloy Steel

Product Type : Other, Rolling Mill Guide

Cast Iron And Steel Rolls

Price 10000.00 USD ($) / Piece

Minimum Order Quantity : 2 Pieces

Technology : Other, Centrifugal Casting, Static Casting

Weight : Vary as per roll size (typically 500 kg to Several Tons)

Material : Cast Iron, Alloy Steel

Product Type : Other, Cast Iron and Steel Rolls

Gear Shaft

Price 1000 USD ($)

Minimum Order Quantity : 2 Pieces

Technology : Other, CNC Machined

Weight : 7.5 kg (example)

Material : Alloy Steel

Product Type : Other, Gear Shaft

Tungsten carbide roll ring

Price 1000 USD ($)

Minimum Order Quantity : 2 Pieces

Technology : Other, Sintered

Weight : Variable

Material : Tungsten Carbide

Product Type : Other, Tungsten Carbide Roll Ring