Rolling Mill Guide

Rolling Mill Guide Specification

- Diameter

- Up to 200 mm (or as required)

- Usage & Applications

- Guiding and aligning rolled stock in continuous rolling mills

- Features

- High wear resistance, Easy installation, Precise guiding

- Noise Level

- Low

- Size

- Standard and Custom sizes available

- Drive Type

- Mechanical

- Lubricating System

- Centralized or Manual Lubrication

- Motor Power

- As per rolling mill requirement

- Surface Finish

- Smooth, Precision Finished

- Capacity

- Suitable for medium and heavy-duty rolling mills

- Shape

- Rectangular/Footer Guide Shape

- Product Type

- Rolling Mill Guide

- Material

- High-grade Alloy Steel

- Technology

- Hot Rolling Mill Technology

- Power Source

- Electric

- Power

- Customizable as per requirement

- Voltage

- 220-440 V

- Surface Treatment

- Polished and Hardened

- Dimension (L*W*H)

- Depends on Model and Capacity

- Weight

- Varies as per specification

- Color

- Silver/Grey

- Corrosion Resistance

- Enhanced with special coatings

- Compatibility

- Universal fit for most rolling mill stands

- Construction Type

- Single Piece/Segmented available

- Installation Position

- Entry/Exit/Intermediate Guides

- Packing Type

- Wooden Box or as per customer requirement

- Operating Temperature Range

- Up to 500°C

- Application Industry

- Steel, Aluminum, Copper Rolling Mills

- Maintenance

- Low maintenance required

Rolling Mill Guide Trade Information

- Minimum Order Quantity

- 2 Sets

- FOB Port

- Shanghai

- Payment Terms

- Letter of Credit at Sight (Sight L/C), Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID)

- Supply Ability

- 30000 Sets Per Year

- Delivery Time

- 30 Days

- Packaging Details

- wooden cases

- Main Export Market(s)

- South America, Western Europe, Middle East, Australia, Asia, Central America, Eastern Europe, North America, Africa

About Rolling Mill Guide

Efficient Application and Key Features of Rolling Mill Guide

Our rolling mill guide offers a seamless application method, easily installed at entry, exit, or intermediate positions to guide and align rolled stock. Its special features include high wear resistance, a choice between single-piece or segmented construction, and enhanced corrosion resistance. The site of application spans steel, aluminum, and copper rolling mills, ensuring it fits a variety of systems. Enjoy smooth operations, accuracy, and a reduced noise level with our precision-finished rolling mill guide.

Supply Capacity, Delivery and Market Coverage

We offer a consistent supply ability with prompt drop-offs and deliveries tailored to your schedule. Rolling mill guides are delivered securely, packed in sturdy wooden boxes or as per your requirements, ensuring pristine condition upon arrival. Our supply network spans leading domestic markets, providing reliable support for distributors, exporters, manufacturers, suppliers, and traders. Regardless of your order size or specification, we champion timely delivery and gilded customer satisfaction across China and beyond.

FAQs of Rolling Mill Guide:

Q: How does the rolling mill guide enhance operational efficiency?

A: The rolling mill guide is engineered for precise guiding and alignment of rolled stock, reducing friction and wear while ensuring smooth passage. This mechanism increases production efficiency and yields a consistent product quality.Q: What are the installation options for this rolling mill guide?

A: You can install the guide at the entry, exit, or intermediate positions of your rolling mill stand. Its universal compatibility allows it to fit most systems easily, whether you require a single piece or segmented construction.Q: When should I consider using a corrosion-resistant rolling mill guide?

A: Corrosion-resistant features are crucial when working in environments with high humidity, exposure to water, or aggressive chemical agents. The special coatings on our guide safeguard its performance and extend service life in such conditions.Q: Where is the ideal application site for this rolling mill guide?

A: It is optimally used in steel, aluminum, or copper rolling mills, serving as an essential component in medium and heavy-duty operations for continuous guiding and alignment of stock across various mill configurations.Q: What is the benefit of using a centralized lubricating system with your rolling mill guide?

A: A centralized lubricating system ensures consistent lubrication, minimizing maintenance needs and reducing downtime. This translates to an overall extended service life and champion-level reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rolling Mill Machinery Parts Category

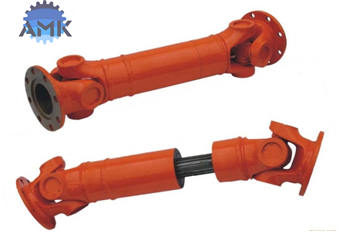

Universal Shaft Coupling

Price 1000 USD ($) / Piece

Minimum Order Quantity : 2 Pieces

Material : Alloy Steel / Carbon Steel

Product Type : Other, Universal Shaft Coupling

Technology : Other, Machined

Weight : Depends on size and material (generally 220 kg)

Cast Iron And Steel Rolls

Price 10000.00 USD ($) / Piece

Minimum Order Quantity : 2 Pieces

Material : Cast Iron, Alloy Steel

Product Type : Other, Cast Iron and Steel Rolls

Technology : Other, Centrifugal Casting, Static Casting

Weight : Vary as per roll size (typically 500 kg to Several Tons)

Gear Shaft

Price 1000 USD ($)

Minimum Order Quantity : 2 Pieces

Material : Alloy Steel

Product Type : Other, Gear Shaft

Technology : Other, CNC Machined

Weight : 7.5 kg (example)

Rolling Bearings

Price 100 USD ($) / Piece

Minimum Order Quantity : 5 Pieces

Material : High Carbon Chromium Steel

Product Type : Other, Rolling Bearings

Technology : Other, Precision Machining

Weight : Varies with Size