Gear Shaft

Gear Shaft Specification

- Lubricating System

- Manual or Centralized

- Size

- Customizable

- Diameter

- 60 mm (example)

- Shape

- Cylindrical

- Noise Level

- Low

- Drive Type

- Spline

- Capacity

- High Torque Transmission

- Features

- Precision Engineered, High Durability, Corrosion Resistant

- Surface Finish

- Polished

- Usage & Applications

- Industrial Machinery, Transmission Assemblies

- Product Type

- Gear Shaft

- Material

- Alloy Steel

- Technology

- CNC Machined

- Power Source

- Mechanical

- Surface Treatment

- Hardened & Ground

- Dimension (L*W*H)

- 400 mm x 60 mm x 60 mm (example)

- Weight

- 7.5 kg (example)

- Color

- Silver/Grey

Gear Shaft Trade Information

- Minimum Order Quantity

- 2 Pieces

- FOB Port

- Shanghai

- Delivery Time

- 45 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- wooden cases

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Gear Shaft

Gear Shafts

Gear shaftis a mechanical part which support rotating parts for passing movement ,torqueand flexural moment.

Productionstandard: DIN 3972,DIN867 Standard.

Material:According to customer requirement.

Exceptional Strength and Precision

Our gear shafts are crafted from premium alloy steel and undergo advanced CNC machining, followed by hardening and grounding, ensuring each piece meets stringent quality standards. Achieving a hardness of 56-62 HRC, these shafts facilitate high torque transmission while maintaining low noise and extended operational life.

Versatile Application & Customized Solutions

With both standard and custom mounting options and compatibility with a range of gearboxes and assemblies, these shafts offer versatile installation. Their adaptability makes them ideal for various industrial machinery, transmission assemblies, and more. Sizes, thread types, and lubrication systems are customizable to suit specific operational requirements.

Quality Assurance and Reliable Supply

Each gear shaft undergoes comprehensive 100% dimensional and metallurgical inspection, adhering to AGMA and DIN manufacturing standards. With a production capacity of up to 10,000 units per month and robust packaging, clients benefit from timely, large-scale deliveries whether as a distributor, exporter, manufacturer, supplier, or trader.

FAQs of Gear Shaft:

Q: How resistant is this gear shaft to wear, rust, and corrosion?

A: The shafts surface is hardened to 56-62 HRC and treated with advanced polishing and grinding techniques, providing excellent resistance to wear, rust, and corrosioneven in demanding industrial environments.Q: What mounting types and sizes are available for this gear shaft?

A: Standard and custom mounts are available to ensure compatibility with diverse gearboxes and assemblies. We offer customizable sizes, including threads (Metric or UNF upon request), to meet specific project needs.Q: When should I choose a custom gear shaft configuration?

A: Opting for a custom configuration is recommended if your assembly requires non-standard dimensions, unique mounting, specific thread types, or tailored lubrication systems to fit specialized machinery or challenging applications.Q: Where can this gear shaft be used?

A: Ideal for industrial machinery, transmission assemblies, and heavy-duty applications, this gear shaft fits both standard gearboxes and custom assemblies, offering reliability in varied operational contexts such as manufacturing plants and automation systems.Q: What is the manufacturing and inspection process for these shafts?

A: Each gear shaft is CNC machined from high-grade alloy steel, heat-treated for hardness, then ground and polished. 100% dimensional and metallurgical inspection ensures compliance with AGMA or DIN standards, guaranteeing precise performance.Q: How does using this gear shaft benefit my operations?

A: You gain a combination of high durability, low maintenance, quiet operation, and superior torque transmission. Its strong resistance to environmental factors and customizable features translate to increased reliability and reduced operational costs.Q: What packaging options are provided and how does it ensure safe delivery?

A: We offer secure packaging in wooden boxes or cartons, protecting each gear shaft from damage during transit, ensuring you receive products in perfect condition no matter your global location.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rolling Mill Machinery Parts Category

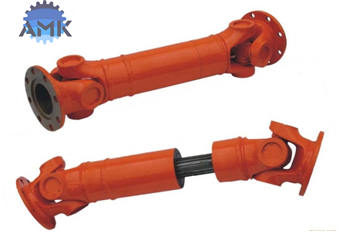

Universal Shaft Coupling

Price 1000 USD ($) / Piece

Minimum Order Quantity : 2 Pieces

Technology : Other, Machined

Material : Alloy Steel / Carbon Steel

Product Type : Other, Universal Shaft Coupling

Weight : Depends on size and material (generally 220 kg)

Forged Steel Rolls

Price 10000 USD ($)

Minimum Order Quantity : 2 Pieces

Technology : Other, Hot Forging

Material : Forged Steel

Product Type : Other, Forged Steel Rolls

Weight : 1 to 50 Tons (as per design)

Cast Iron And Steel Rolls

Price 10000.00 USD ($) / Piece

Minimum Order Quantity : 2 Pieces

Technology : Other, Centrifugal Casting, Static Casting

Material : Cast Iron, Alloy Steel

Product Type : Other, Cast Iron and Steel Rolls

Weight : Vary as per roll size (typically 500 kg to Several Tons)

Tungsten carbide roll ring

Price 1000 USD ($)

Minimum Order Quantity : 2 Pieces

Technology : Other, Sintered

Material : Tungsten Carbide

Product Type : Other, Tungsten Carbide Roll Ring

Weight : Variable