Tungsten carbide roll ring

Tungsten carbide roll ring Specification

- Features

- High hardness, corrosion resistance, long lifespan

- Capacity

- High wear resistance for continuous use

- Usage & Applications

- Steel wire rod, bar and rebar rolling mills

- Shape

- Ring / Circular

- Surface Finish

- Mirror/Polished

- Size

- Customizable

- Diameter

- Available from 50 mm to 500 mm

- Product Type

- Tungsten Carbide Roll Ring

- Material

- Tungsten Carbide

- Technology

- Sintered

- Power Source

- Manual

- Surface Treatment

- Polished

- Dimension (L*W*H)

- As per customer specification

- Weight

- Variable

- Color

- Grey / Metallic

Tungsten carbide roll ring Trade Information

- Minimum Order Quantity

- 2 Pieces

- FOB Port

- Shanghai

- Delivery Time

- 45 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- wooden cases

- Main Export Market(s)

- Middle East, Africa, Western Europe, Australia, South America, North America, Central America, Eastern Europe, Asia

- Main Domestic Market

- All India

About Tungsten carbide roll ring

Tungsten Carbide Roll Rings

High qualitytungsten carbide roll rings for rolling mill are widely used as seal faces withresistant-wearing, high fracturing strength, high thermal conductivity, smallthermal expansion coefficient. It is the best material to resist heat andfracture in all hard face materials.

Property:

1. Highhardness & good wear resistance. Normal hardness reaches HRA 78-89, undertemperature 600 ,beyond hardness of high speed steel

2. Highelasticity modulus

3. Highmechanical strength, compressive strength is up to 6000MN/M2

4. Highdensity

5. Goodthermal conductivity

6. Goodcorrosion& oxidation resistance

Exceptional Durability and Performance

Built from premium tungsten carbide and cobalt bonding, these roll rings withstand the toughest industrial environments. The high hardness, corrosion resistance, and superior impact absorption make them ideal for continuous, heavy-duty operations in rolling mills. Their extended lifespan reduces maintenance frequency and operational interruptions.

Advanced Manufacturing With Hot Isostatic Pressing

Each ring is produced using an advanced Hot Isostatic Pressing (HIP) process. This state-of-the-art method ensures improved material density, structural integrity, and uniformity. As a result, users benefit from outstanding strength and resistance to deformation even under extreme pressures and temperatures.

Customizable Solutions for Diverse Requirements

From diameter to finish and dimensions, these roll rings can be tailored to meet unique project requirements. Whether for steel wire rod or heavy bar rolling, customization options enable precise compatibility. Orders are packed securely in wooden cases and supported by reliable quality assurance and test certifications.

FAQs of Tungsten carbide roll ring:

Q: How are tungsten carbide roll rings manufactured for high precision and durability?

A: These roll rings are engineered using a Hot Isostatic Pressing (HIP) process, resulting in exceptional density and uniformity. This technique, combined with thorough surface polishing and quality checks, ensures robust performance and longevity in high-stress environments.Q: What are the main benefits of using these roll rings in wire and rebar rolling mills?

A: They offer maximum hardness, superior wear and impact resistance, and excellent thermal conductivity, all of which contribute to extended service life, reduced downtime, and lower maintenance needs in continuous rolling operations.Q: When should these tungsten carbide roll rings be considered for industrial applications?

A: These rings are best employed when high wear resistance, precise dimensional control, and reliability are crucialspecifically in steel wire, bar, or rebar rolling mills facing demanding operational loads and frequent usage.Q: Where can these tungsten carbide roll rings be utilized?

A: Primarily, their application is in the metallurgical and iron & steel sectors, notably in wire rod, bar, and rebar rolling mills. Their robust characteristics also support use in related manufacturing processes demanding durability.Q: What customization options are available for these roll rings?

A: Customization is available for diameter (ranging from 50 mm to 500 mm), size, surface finish (mirror or polished), and dimensions (L*W*H), ensuring precise compatibility with customer specifications and equipment requirements.Q: How is quality assured for these roll rings before delivery?

A: Each ring undergoes comprehensive quality testing for dimensional accuracy and material integrity, including the provision of a Material Test Certificate for tensile strength. Secure wooden case packaging safeguards the product during shipping.Q: What is the process for ordering and receiving a customized tungsten carbide roll ring?

A: Customers can specify their application requirementssuch as dimensions, diameter, and surface finish. The manufacturing process incorporates these needs, followed by stringent quality checks and secure packaging for delivery.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rolling Mill Machinery Parts Category

Rolling Mill Guide

Price 1000 USD ($) / Set

Minimum Order Quantity : 2 Sets

Weight : Varies as per specification

Product Type : Other, Rolling Mill Guide

Material : Highgrade Alloy Steel

Technology : Other, Hot Rolling Mill Technology

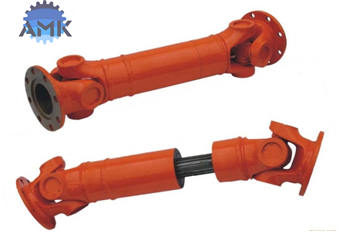

Universal Shaft Coupling

Price 1000 USD ($) / Piece

Minimum Order Quantity : 2 Pieces

Weight : Depends on size and material (generally 220 kg)

Product Type : Other, Universal Shaft Coupling

Material : Alloy Steel / Carbon Steel

Technology : Other, Machined

Cast Iron And Steel Rolls

Price 10000.00 USD ($) / Piece

Minimum Order Quantity : 2 Pieces

Weight : Vary as per roll size (typically 500 kg to Several Tons)

Product Type : Other, Cast Iron and Steel Rolls

Material : Cast Iron, Alloy Steel

Technology : Other, Centrifugal Casting, Static Casting

Forged Steel Rolls

Price 10000 USD ($)

Minimum Order Quantity : 2 Pieces

Weight : 1 to 50 Tons (as per design)

Product Type : Other, Forged Steel Rolls

Material : Forged Steel

Technology : Other, Hot Forging