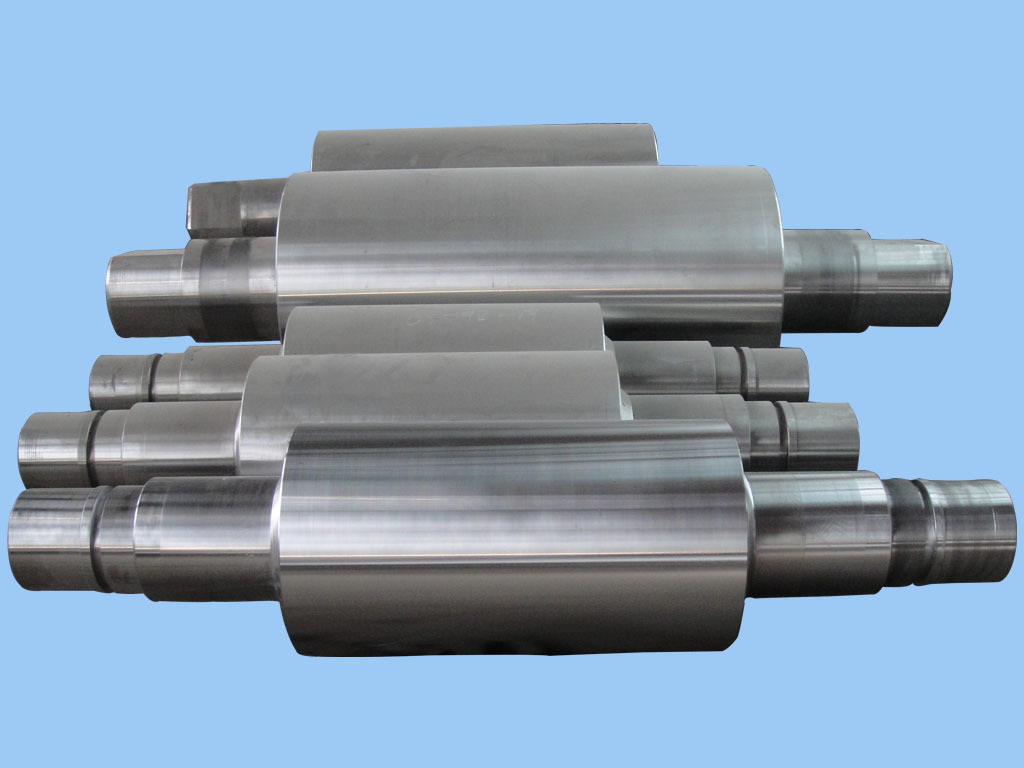

Cast Iron And Steel Rolls

Cast Iron And Steel Rolls Specification

- Diameter

- As per client requirement, up to 1500 mm

- Drive Type

- Driven by Mill Machine

- Lubricating System

- Oil Grease Film Lubrication

- Usage & Applications

- Rolling Mills, Steel Plants, Metal Processing Units

- Size

- Custom sizes available

- Capacity

- High Duty, Continuous Operation

- Noise Level

- Low

- Features

- Wear Resistant, High Strength, Shock Proof, Excellent Surface Finish

- Shape

- Cylindrical

- Surface Finish

- Ground/Peeled, Polished, Precision Finished

- Product Type

- Cast Iron and Steel Rolls

- Material

- Cast Iron, Alloy Steel

- Technology

- Centrifugal Casting, Static Casting

- Power Source

- Mechanical

- Surface Treatment

- Polished, Hardened Surface

- Dimension (L*W*H)

- Customized as per specifications

- Weight

- Vary as per roll size (typically 500 kg to Several Tons)

- Color

- Metallic Grey, Silver

- Crack Resistance

- High

- Working Life

- Extended Service Life for Heavy Duty Rolling

- Application Industry

- Hot Strip Mills, Section Mills, Bar Mills, Wire Rod Mills

- Hardness

- Shore 40 to 100 HSD (Depending on Type)

- Magnetic Property

- Non-Magnetic/Core can be Magnetic as per Application

- Maintenance

- Low Maintenance Requirements

- Impact Toughness

- Excellent

- Packing

- Wooden Box/Seaworthy Packing

- Delivery Condition

- Machined and Ready to Use

- Edge Quality

- Precise Edges, Burr-Free

- Roll Type

- Horizontal, Vertical, Intermediate, Universal Rolls

- Customization

- Available as per drawings and specifications

- Heat Treatment

- Quenched and Tempered

- Core Material

- Spheroidal Graphite Iron, Alloyed Steel Core

Cast Iron And Steel Rolls Trade Information

- Minimum Order Quantity

- 2 Pieces

- FOB Port

- Shanghai

- Supply Ability

- 30000 Pieces Per Year

- Delivery Time

- 4 Months

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- steel pallet loaded in container

- Main Export Market(s)

- Eastern Europe, Middle East, Africa, North America, Central America, South America, Australia, Western Europe, Asia

- Main Domestic Market

- All India

About Cast Iron And Steel Rolls

Superior Quality and Versatility

Cast Iron and Steel Rolls from our facility are tailored for a wide array of rolling applications, including hot strip, section, bar, and wire rod mills. With advanced heat treatment (quenched and tempered) and centrifugal or static casting processes, the rolls deliver wear resistance, shock-proof reliability, and a burr-free, precision-finished surface. Custom dimensions and core materials ensure optimal performance and longevity, even under heavy-duty, continuous operation.

Customization and Precision Engineering

Every order can be customized per client drawings and technical specifications. Rolls can be supplied in a range of hardness (Shore 40100 HSD), diameters up to 1500 mm, and with either magnetic or non-magnetic cores. The finished product undergoes rigorous surface treatments, including polishing and hardening, for an exceptional edge quality and ground, peeled, or precision-polished surfaces. This ensures compatibility and maximum performance in various mill environments.

FAQs of Cast Iron And Steel Rolls:

Q: How are Cast Iron and Steel Rolls manufactured to ensure high crack resistance and strength?

A: These rolls are produced using centrifugal or static casting technologies, followed by precise heat treatments such as quenching and tempering. Premium materials like spheroidal graphite iron or alloyed steel cores provide outstanding crack resistance, high impact toughness, and prolonged working life, making them ideal for heavy-duty rolling applications.Q: What industries typically use these rolls, and what are their main applications?

A: Our rolls are primarily used in rolling mills, steel plants, and other metal processing units. They serve key functions in hot strip mills, section mills, bar mills, and wire rod mills, where durable, wear-resistant, and high-capacity rolls are essential for shaping and processing metals.Q: Can these rolls be customized according to specific technical requirements or industry standards?

A: Yes, we offer complete customization based on client drawings and specifications. Rolls can be supplied with tailored hardness, dimensions, surface finishes, core material choices, edge qualities, and magnetic properties to meet unique production needs and applications.Q: What is the delivery condition of these rolls, and how are they packed for export?

A: All rolls are delivered in a fully machined and ready-to-use state, ensuring swift installation. For international shipping and safety, they are securely packed in wooden boxes or appropriate seaworthy packaging to minimize transit damage and contamination.Q: How does the maintenance requirement for these rolls compare to others in the industry?

A: Thanks to advanced surface treatments, robust material selection, and precise manufacturing processes, our rolls require minimal maintenance. Their high crack resistance and excellent impact toughness further reduce downtime and servicing needs, optimizing operational efficiency for users.Q: What are the key benefits of choosing your Cast Iron and Steel Rolls for rolling mills?

A: Key benefits include extended service life under continuous, heavy-duty operation; high wear resistance; accurate, burr-free edges; exceptional surface finish; customizable options; and suitability for both magnetic and non-magnetic core applications. This ensures reliable and cost-effective performance in demanding metal processing environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rolling Mill Machinery Parts Category

Rolling Mill Guide

Price 1000 USD ($) / Set

Minimum Order Quantity : 2 Sets

Material : Highgrade Alloy Steel

Product Type : Other, Rolling Mill Guide

Weight : Varies as per specification

Technology : Other, Hot Rolling Mill Technology

Rolling Bearings

Price 100 USD ($) / Piece

Minimum Order Quantity : 5 Pieces

Material : High Carbon Chromium Steel

Product Type : Other, Rolling Bearings

Weight : Varies with Size

Technology : Other, Precision Machining

Gear Shaft

Price 1000 USD ($)

Minimum Order Quantity : 2 Pieces

Material : Alloy Steel

Product Type : Other, Gear Shaft

Weight : 7.5 kg (example)

Technology : Other, CNC Machined

Tungsten carbide roll ring

Price 1000 USD ($)

Minimum Order Quantity : 2 Pieces

Material : Tungsten Carbide

Product Type : Other, Tungsten Carbide Roll Ring

Weight : Variable

Technology : Other, Sintered