Forged Steel Rolls

Forged Steel Rolls Specification

- Lubricating System

- Centralized Lubrication

- Surface Finish

- Smooth, Mirror Finish

- Motor Power

- As per application

- Noise Level

- Low Noise Operation

- Usage & Applications

- Steel & Metal Rolling Mills, Metal Processing Industries

- Diameter

- 200 mm to 1200 mm

- Drive Type

- Belt or Gear Driven

- Shape

- Cylindrical

- Features

- Wear Resistant, Long Life, High Tensile Strength

- Size

- Standard & Customized

- Capacity

- High Output, As per Specification

- Product Type

- Forged Steel Rolls

- Material

- Forged Steel

- Technology

- Hot Forging

- Power Source

- Electric

- Power

- Custom as per requirement

- Voltage

- 380V / 415V

- Pressure

- High Pressure Rated

- Surface Treatment

- Polished, Heat Treated

- Dimension (L*W*H)

- Customized

- Weight

- 1 to 50 Tons (as per design)

- Color

- Metallic Grey

- Packing

- Sea-worthy Standard Packing

- Processing Type

- Forged and Machined

- Hardness

- 50-105 HSD (as per application)

- Delivery Condition

- Ready to Install

- Impact Resistance

- Excellent

- Production Standards

- International Standards

- Roll Surface Type

- Smooth / Grooved

- Work Life

- Extended Service Life

- Application Temperature Range

- Up to 550°C

- Minimum Order Quantity

- 1 Unit

- Heat Treatment Method

- Quenching and Tempering

- Turnaround Time

- According to order volume

- Customization

- Available as per drawing / requirement

- Core Material

- Alloy Steel/Core Hardened

Forged Steel Rolls Trade Information

- Minimum Order Quantity

- 2 Pieces

- FOB Port

- Shanghai

- Delivery Time

- 4 Months

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Forged Steel Rolls

Forged steel rolls

To forge ingot castings into work rolls, intermediate rolls and backup rolls with compact structure and homogeneous compositions. As a result, forged rolls have better toughness, more uniform surface hardness and better fatigue resistance than cast rolls with the same type.Forged rolls can be applied to hot rolling and cold rolling.

Application for hot rolling:

Hot-rolling blooming and rough rolling for profile steel

Materials:55Mn2,55Cr,60CrMnMo,60SiMnM,etc.As per buyers requirements.

Application for cold rolling:

Widely used as work rolls for cold-rolled sheet.

Materials: 9Cr,9Cr2,9CrV,8CrMoV,8Cr2MoV,92Cr2Mo,92Cr2MoV,9Cr3Mo,8Cr3MoV,8Cr5MoV,etc.As per buyers requirements.

Expertly Engineered for Demanding Applications

Our forged steel rolls are manufactured using premium alloy steels and precise hot forging technology. Each roll is tailored through quenching and tempering, resulting in exceptional durability and a long service life, even under high-temperature conditions up to 550C. Customized solutions are available to match your specific requirements.

Advanced Surface Finishes and Customization

Select from smooth or mirror-finish surfaces, or opt for grooved rolls as per your operations. All rolls undergo polished, heat-treated surface finishing, ensuring optimal performance, low noise, and efficient metal processing. Diameters range from 200 mm to 1200 mm, with additional customization available for dimensions, power, and drive systems.

FAQs of Forged Steel Rolls:

Q: How are forged steel rolls produced, and what ensures their high performance?

A: The rolls are created through hot forging and precision machining, followed by quenching and tempering heat treatment. This process produces a hard, impact-resistant surface and a tough core, ensuring excellent wear resistance and extended lifespan, even under high load and temperature conditions.Q: What are the typical applications of these forged steel rolls?

A: They are designed for use in steel and metal rolling mills, as well as various metal processing industries. Their robust construction and customizable features make them suitable for both heavy-duty and precision applications requiring smooth or grooved roll surfaces.Q: When should I consider customizing the rolls for my application?

A: Customization is recommended when your operation requires specific dimensions, surface types, power ratings, or production parameters not met by standard rolls. We accept drawings and application requirements to deliver a tailored solution for optimal performance.Q: Where are these forged steel rolls commonly supplied and used?

A: These rolls are exported globally, particularly to steel plants, rolling mills, and metalworking industries. As a distributor, manufacturer, and exporter based in China, we provide reliable international delivery with secure, sea-worthy packing.Q: What benefits do forged steel rolls provide in industrial operations?

A: Key advantages include high tensile strength, excellent impact resistance, long operational life, and low noise output. Their robust construction ensures minimal downtime and maximum productivity in demanding rolling and metal processing environments.Q: What is the minimum order quantity and typical delivery time for forged steel rolls?

A: The minimum order quantity is only one unit, accommodating both large and small operational needs. Delivery time varies with order size and customization requirements, and is communicated clearly at the time of order placement.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rolling Mill Machinery Parts Category

Rolling Mill Guide

Price 1000 USD ($) / Set

Minimum Order Quantity : 2 Sets

Weight : Varies as per specification

Product Type : Other, Rolling Mill Guide

Technology : Other, Hot Rolling Mill Technology

Material : Highgrade Alloy Steel

Cast Iron And Steel Rolls

Price 10000.00 USD ($) / Piece

Minimum Order Quantity : 2 Pieces

Weight : Vary as per roll size (typically 500 kg to Several Tons)

Product Type : Other, Cast Iron and Steel Rolls

Technology : Other, Centrifugal Casting, Static Casting

Material : Cast Iron, Alloy Steel

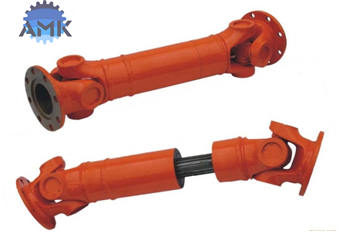

Universal Shaft Coupling

Price 1000 USD ($) / Piece

Minimum Order Quantity : 2 Pieces

Weight : Depends on size and material (generally 220 kg)

Product Type : Other, Universal Shaft Coupling

Technology : Other, Machined

Material : Alloy Steel / Carbon Steel

Gear Shaft

Price 1000 USD ($)

Minimum Order Quantity : 2 Pieces

Weight : 7.5 kg (example)

Product Type : Other, Gear Shaft

Technology : Other, CNC Machined

Material : Alloy Steel