Eaf Ceramic Coated And Calorized Oxygen Lance Pipe

Eaf Ceramic Coated And Calorized Oxygen Lance Pipe Specification

- Surface Treatment

- Ceramic Coated and Calorized

- Pressure Ratings

- Up to 10 kg/cm

- Features

- Extended Service Life, Reduced Pipe Consumption, Enhanced Safety

- Automation Grade

- Manual/Semi-Automatic

- Used For

- Oxygen Blowing, Decarburization, Bottom Stirring

- Operating Temperature

- Up to 1700C

- Material

- Mild Steel with Ceramic Coating and Calorized Layer

- Style

- Seamless, Round Pipe

- Properties

- High Thermal Resistance, Anti-Oxidation, Anti-Corrosion

- Capacity

- Customizable as per Requirement

- Power

- Not Applicable (Manual/Mechanical Insertion)

- Condition

- New

- Application

- Electric Arc Furnace (EAF) Steelmaking, Foundries, Metallurgical Industries

Eaf Ceramic Coated And Calorized Oxygen Lance Pipe Trade Information

- Minimum Order Quantity

- 100 Pieces

- FOB Port

- Shanghai

- Payment Terms

- Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cash Against Delivery (CAD)

- Supply Ability

- 30000 Pieces Per Year

- Delivery Time

- 25 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- standard export package

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Eaf Ceramic Coated And Calorized Oxygen Lance Pipe

Eaf Ceramic Coated And Calorized Oxygen Lance Pipe

(Calorized & Ceramic Coated Oxygen Lance Pipe)

We supply all the types of oxygen lance pipes according to your requirement.

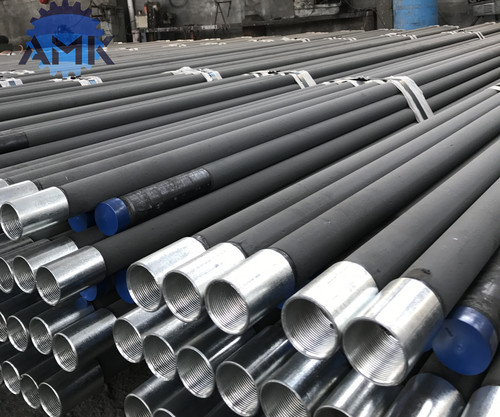

Oxygen Lance is a hollow electric welded tube

Oxygen Lance Pipe comes in a variety of end finishes. End caps are provided to prevent contamination. Oxygen Lancing is a reliable method for tapping heats or for other production operations.

Oxygen Lance Pipe is used to remove the carbon from molten metal. During the steel making process, a desired carbon content is attained by injecting oxygen into the molten metal. This process is used in blast furnaces, basic oxygen furnaces and also induction and electric furnaces

Lances are used for opening furnace tap holes, cleaning ladle well blocks,unclogging tundish nozzles, cutting ferrous materials, providing the steel or iron is hot enough to sustain burning, ie cutting skills, spill clean-up, etc.

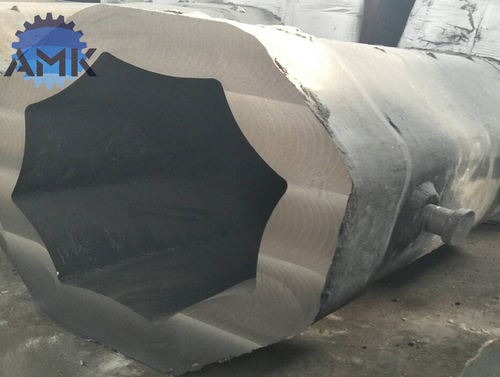

Superior Durability and Heat Resistance

Thanks to the innovative combination of ceramic coating and calorization, these oxygen lance pipes provide outstanding heat and oxidation resistance even during prolonged exposure to high temperatures. This ensures a much longer operational lifespan and safer oxygen delivery in metallurgical applications, reducing the risk of pipe failure.

Customizable Specifications for Every Need

With customizable specifications in thickness, diameter, and length, these pipes can be tailored to fit your specific operational requirements. Whether you need shorter lengths for compact spaces or extra thickness for heavy-duty applications, our solutions cater to all EAF and foundry settings.

Enhanced Process Efficiency and Safety

Our pipes not only extend service life but also help minimize the frequency of pipe replacements, lowering overall consumption and reducing downtime. The double protective layer elevates safety, allowing for consistent oxygen blowing without loss of structural integrity, optimizing process performance.

FAQs of Eaf Ceramic Coated And Calorized Oxygen Lance Pipe:

Q: How does the ceramic coating and calorized layer improve the pipes performance during oxygen blowing?

A: The ceramic coating and calorized layer provide a dual protective barrier against extreme heat and oxidative environments. This combination prevents rapid degradation of the pipe, greatly enhancing its lifespan and maintaining efficient oxygen flow even under temperatures up to 1700C.Q: What customization options are available for the oxygen lance pipes dimensions?

A: These pipes offer full customization in thickness (2.5 mm to 6.0 mm), outer diameter (21 mm to 100 mm), and lengths ranging from 2 m to 6 m or tailor-made sizes. Color and joint types (threaded or socket weldable) can also be customized as per operational requirements.Q: When should I consider using a ceramic coated and calorized lance pipe over standard pipes?

A: You should use this advanced lance pipe when your process involves prolonged oxygen blowing, high operational temperatures, or requires minimizing oxidation and corrosion. It is particularly suitable for applications demanding extended service life and higher safety, like EAF steelmaking and high-intensity foundry operations.Q: Where are these oxygen lance pipes commonly used?

A: They are widely employed in electric arc furnace steelmaking, foundries, and metallurgical industries, mainly for oxygen blowing, decarburization, bottom stirring, and similar high-temperature, high-demand processes.Q: What is the primary process benefit of switching to these ceramic coated and calorized pipes?

A: Switching to these pipes substantially reduces pipe consumption rates and downtime for replacement, while enhancing operational safety. Their superior resistance to heat and oxidation ensures stable, prolonged use, improving overall process efficiency and reliability.Q: How does the pipes inner bore quality affect its function?

A: The smooth, scale-free inner bore ensures unimpeded oxygen flow and reduces turbulence, contributing to more efficient and stable blowing operations while minimizing clogging or flow restrictions.Q: What are the advantages of seamless construction in these pipes?

A: The seamless, round design provides greater structural integrity, reducing the risk of leaks or fractures during high-pressure and high-temperature oxygen blowing. This enhances safety and longevity in demanding metallurgical environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Metallurgical Consumable Category

Molten Steel Sampler

Price 1-2 USD ($) / Piece

Minimum Order Quantity : 1000 Pieces

Material : Paper tube with heatresistant probe

Condition : New

Properties : Rapid and accurate steel sampling

Operating Temperature : Up to 1700C

Expendable Thermocouple

Price 1 USD ($) / Piece

Minimum Order Quantity : 100 Pieces

Material : HighQuality Quartz or Ceramic Paper Tube

Condition : New

Properties : High Accuracy, Rapid Response, Disposable

Operating Temperature : Up to 1800C

Ingot Mould

Price 10000 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Material : Cast Iron

Condition : New

Properties : High Durability, Strong Thermal Conductivity, Crack Resistant

Operating Temperature : Up to 1400C

Slag Pot

Price 15000 USD ($) / Set

Minimum Order Quantity : 1 Set

Material : Cast Iron and Steel

Condition : New