Molten Steel Sampler

Molten Steel Sampler Specification

- Surface Treatment

- Heat-resistant coated exterior

- Operating Temperature

- Up to 1700C

- Automation Grade

- Manual

- Used For

- Collecting molten steel samples

- Features

- Disposable, Fast response, Consistent results, Lightweight

- Pressure Ratings

- Atmospheric

- Power Source

- No external power required

- Material

- Paper tube with heat-resistant probe

- Style

- Handheld insertion

- Properties

- Rapid and accurate steel sampling

- Capacity

- Single sample extraction per use

- Power

- Manual operation

- Condition

- New

- Application

- Steel mills, foundries, steelmaking process

- Compatibility

- Suitable for various ladle and converter sizes

- Probe Length

- Standard 600 mm (customizable)

- Packaging

- Industrial grade, as per client requirement

- Sampling Time

- Within 3-5 seconds

- Disposable / Reusable

- Disposable

- Sample Type

- Molten Steel

Molten Steel Sampler Trade Information

- Minimum Order Quantity

- 1000 Pieces

- FOB Port

- Shanghai

- Payment Terms

- Letter of Credit at Sight (Sight L/C), Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID)

- Supply Ability

- 300000 Pieces Per Year

- Delivery Time

- 30 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- wooden pallet

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

About Molten Steel Sampler

Immerse Sampler

Immerse sampler is used to collect moltensteel sample quickly for spectral analysis which is widely used in electric arcfurnace, converter furnace, tundish, ladle furnace, continuous casting,secondary refining,etc. Its main characteristics are simple structure andconvenient application.

Main technical parameter

- Sampling test qualified rate 99 Percent.

- Steel sample: Intact, dense, smooth, noporosity.

Using Method

- Insert the sampler into the specific measuring lance.

- The slag must be broken firstly if it isthick or hard.

- During measurement, the depth of sampling can be 350-400mm, holdingfor 4 to 6 seconds.

- The sampler need to be removed from the molten steel and knocked tothe ground after cooling off,then you get the sample.

- The molten steel temperature should be above 1500 Steelduring sampling.

Questions to understand your requirement:

1.Shape of the steel sample, Round or Oval?

2.Whats about the cardboard? Length? Outter diameter and inner diameter?

3.Whats the material of Deoxidizer?Aluminium or Zirconium or nothing?

4.Order Quantity

Efficient Steel Sampling for Quality Assurance

Obtain quick and reliable molten steel samples directly from process ladles and converters using this advanced disposable sampler. Its ergonomic hand-held design allows for swift manual operation, while the heat-resistant construction ensures durability and safety during usage. Suitable for demanding environments, it supports consistent process monitoring and quality assessment with every single extraction.

Customizable and Practical Design

With a standard probe length of 600 mm and options for customization, this sampler adapts to various client specifications and vessel sizes. The assembly features a lightweight paper tube and a heat-resistant coated exterior, tailored to meet stringent industrial requirements. Delivered in industrial-grade packaging, it guarantees product integrity and user convenience from manufacturer to operation floor.

FAQs of Molten Steel Sampler:

Q: How does the Molten Steel Sampler operate to collect molten steel samples?

A: The sampler is used by manually inserting its heat-resistant probe into the molten steel inside a ladle or converter. In just 3-5 seconds, it extracts a representative sample, ensuring minimal disturbance to ongoing processes.Q: What types of environments is this sampler compatible with?

A: This device is designed for use in steel mills, foundries, and other steelmaking processes. It accommodates various ladle and converter sizes, making it versatile across industrial applications.Q: When should I use the Molten Steel Sampler during the steelmaking process?

A: The sampler is typically used during key process stages where quick, representative samples are required for quality control and chemical analysis. Sampling at these critical moments helps optimize product quality.Q: Where is this sampler best applied within a steel plant?

A: Ideal application points include near converters, electric arc furnaces, or ladle metallurgy stationsany location where molten steel is accessible and sampling is necessary for process monitoring or laboratory testing.Q: What is the process for using the Molten Steel Sampler safely?

A: Operators should wear approved protective gear, insert the hand-held probe into the molten steel, and retrieve it promptly after 3-5 seconds. The samplers heat-resistant properties and disposable design enable safe and efficient operation.Q: What are the benefits of using this sampler over traditional sampling tools?

A: This disposable device offers rapid response, high accuracy, consistent results, and simplicity of use. Its lightweight, manual operation reduces downtime, improving efficiency in steel production sampling tasks.Q: Is customization available for this molten steel sampling device?

A: Yes, the sampler boasts a standard 600 mm probe but can be tailored in length and packaging to meet specific client and application requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Metallurgical Consumable Category

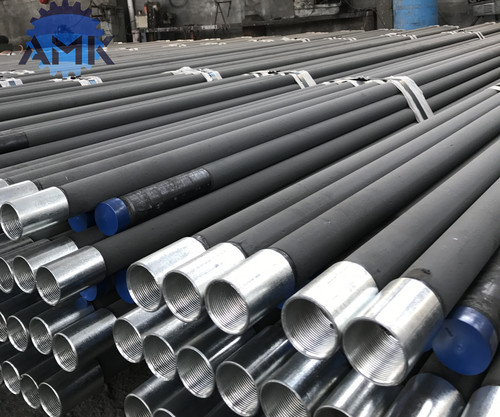

Eaf Ceramic Coated And Calorized Oxygen Lance Pipe

Price 10 USD ($) / Piece

Minimum Order Quantity : 100 Pieces

Material : Mild Steel with Ceramic Coating and Calorized Layer

Condition : New

Used For : Oxygen Blowing, Decarburization, Bottom Stirring

Capacity : Customizable as per Requirement

Expendable Thermocouple

Price 1 USD ($) / Piece

Minimum Order Quantity : 100 Pieces

Material : HighQuality Quartz or Ceramic Paper Tube

Condition : New

Used For : Steel Foundries, Iron Casting, Ferrous/NonFerrous Metallurgy

Capacity : Single Use / Expendable

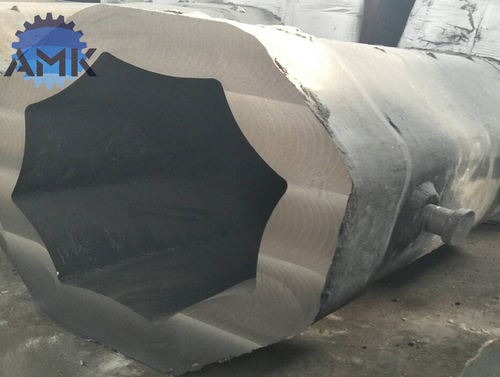

Ingot Mould

Price 10000 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Material : Cast Iron

Condition : New

Used For : Metal Ingot Formation

Capacity : Up to 50 kg (varies by model)

Slag Pot

Price 15000 USD ($) / Set

Minimum Order Quantity : 1 Set

Material : Cast Iron and Steel

Condition : New