Ingot Mould

Ingot Mould Specification

- Load Capacity

- Dependent on Model (Up to 50 kg)

- Operating Temperature

- Up to 1400C

- Surface Treatment

- Sand Blasted / Smooth Finish

- Features

- Wear Resistance, Optimal Solidification Rate, Uniform Cooling

- Used For

- Metal Ingot Formation

- Pressure Ratings

- Atmospheric

- Automation Grade

- Manual

- Material

- Cast Iron

- Style

- Rectangular

- Properties

- High Durability, Strong Thermal Conductivity, Crack Resistant

- Capacity

- Up to 50 kg (varies by model)

- Condition

- New

- Application

- For Melting and Casting Metals

Ingot Mould Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Shanghai

- Supply Ability

- 30000 Pieces Per Year

- Delivery Time

- 45 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- wooden pallet

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

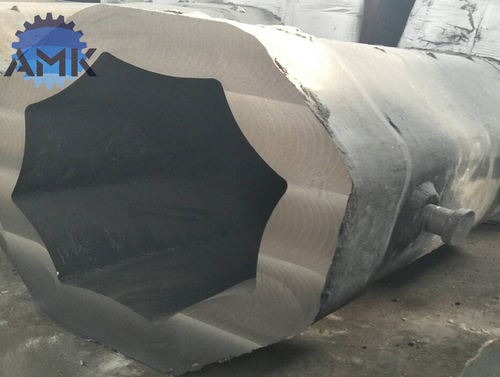

About Ingot Mould

Ingot Mould

We supply square,rectangular,round,polygonal and irregular ingot moulds with different weightsand materials as per customers requirements.

Weight range: From 10Kgs to 200 Tons

Material: Heat resisting cast iron,nodular cast iron,grey cast iron, cast steel and so on.

Custom Sizing for Every Requirement

Every foundry process is unique. Our ingot moulds are available in custom sizes and shapes to precisely match your project needs. Whether you require rectangular, square, or tapered designs, and a wall thickness between 18mm and 60mm, we craft moulds according to your drawings or specifications, ensuring the perfect fit for every application.

Durable Design for Challenging Environments

Engineered from robust cast iron and crafted by the gravity casting method, these moulds exhibit exceptional wear resistance and crack resistance, even at high temperatures up to 1400C. Their strong thermal conductivity supports efficient solidification and uniform cooling, making them ideal for challenging industrial and metallurgical environments.

FAQs of Ingot Mould:

Q: How can I request a custom ingot mould size or shape?

A: You can request custom sizes or shapes by providing your drawings or detailed specifications. We manufacture ingot moulds to fit your exact requirements, accommodating rectangular, square, or tapered shapes and wall thicknesses ranging from 18mm to 60mm.Q: What standards do your ingot moulds comply with?

A: Our moulds are produced in accordance with ISO and ASTM specifications, ensuring high quality and consistent performance for demanding foundry, steel plant, and metallurgical operations.Q: When is it necessary to use gravity casting for ingot mould production?

A: Gravity casting is essential when a defect-free, dense cast iron mould is required to ensure strong durability, precise dimensions, and excellent surface finishideal for metal ingot formation across various industrial settings.Q: Where are these moulds typically used?

A: Our ingot moulds are widely used in foundries, steel plants, and metallurgical industries for melting, casting, and forming metal ingots. Their robust design and resistance to corrosion make them suitable for both domestic and export applications.Q: What is the process for using these ingot moulds in metal casting?

A: During operation, molten metal is poured into the moulds cavity, where it solidifies into the desired ingot shape. The strong thermal conductivity and smooth, sand-blasted or finished surfaces ensure optimal solidification and uniform cooling.Q: What are the main benefits of your ingot moulds?

A: Key benefits include high durability, strong crack resistance, wear resistance, and a long service life. Their customizable capacity (up to 50 kg per model), reliable thermal properties, and compliance with industry standards make them a smart choice for metal casting needs.Q: How are the ingot moulds packaged and shipped?

A: All moulds are securely packaged in sturdy wooden crates or export packing to ensure safe delivery, whether shipped locally or internationally.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Metallurgical Consumable Category

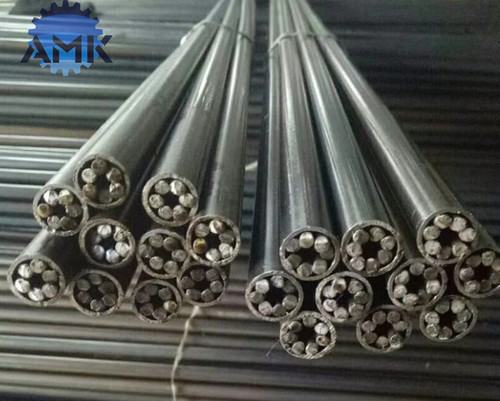

Thermal Lance Pipe

Price 5 USD ($) / Piece

Minimum Order Quantity : 100 Pieces

Material : Steel

Condition : New

Operating Temperature : Up to 4000C

Power Source : Oxygen Supply

Molten Steel Sampler

Price 1-2 USD ($) / Piece

Minimum Order Quantity : 1000 Pieces

Material : Paper tube with heatresistant probe

Condition : New

Operating Temperature : Up to 1700C

Power Source : No external power required

Expendable Thermocouple

Price 1 USD ($) / Piece

Minimum Order Quantity : 100 Pieces

Material : HighQuality Quartz or Ceramic Paper Tube

Condition : New

Operating Temperature : Up to 1800C

Power Source : Not Required (Passive Device)

Slag Pot

Price 15000 USD ($) / Set

Minimum Order Quantity : 1 Set

Material : Cast Iron and Steel

Condition : New