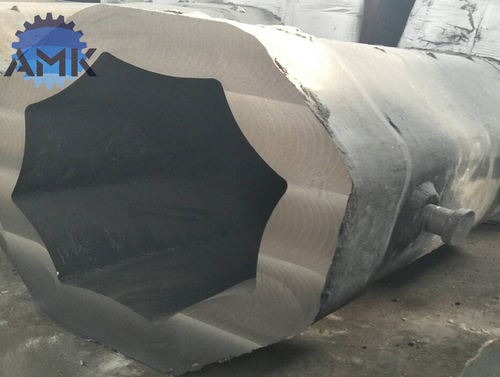

Slag Pot

Slag Pot Specification

- Material

- Cast Iron and Steel

- Condition

- New

Slag Pot Trade Information

- Minimum Order Quantity

- 1 Set

- FOB Port

- Shanghai

- Payment Terms

- Cash Against Delivery (CAD), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cash in Advance (CID)

- Supply Ability

- 30000 Sets pcs Per Year

- Delivery Time

- 60 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Packaging Details

- wooden cases

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- ISO, CE

About Slag Pot

The slag pot is an important steel making equipment in the metallurgical industry. It is a container used to contain high-temperature molten slag generated in the process of steel smelting. It has a bowl-shaped container with lifting trunnions on both sides.In production practice, the use of slag pot in ferro alloy smelting mainly has the following problems:

(1) Due to the design of the overflow port of the slag pot, the center of gravity of the slag pot is shifted, and the slag pot is inclined during the lifting process, and the slag liquid is easy to overflow, and there is a big hidden danger.

(2) The overall structure of the slag pot is unreasonable. After the thermal stress is applied, cracks are easily generated, and the cracks will cause bag penetration.

(3) It is designed to use one lined molten iron ladle and three slag ladle. Sometimes too much molten iron will overflow from the molten iron ladle into the slag pot, causing the temperature at the bottom of the slag pot to rise sharply, which will cause damage to the slag pot.

Improvement measures

1. Thicken the wall thickness of the slag pot inside the rear of the slag pot, so that the center of gravity can be balanced after the slag pot is lifted.

2. The improvement part is the removal of the upper reinforced side of the slag pot, the bottom and middle and upper parts of the slag pot are evenly thin, the bottom reinforced side is reserved for expansion joints, and the bottom is increased with strong ribs.

3. Change the structure of the tapping cart, from the original combination of three slag pot with a lined molten iron ladle to two lined molten iron ladles and two slag pot, which can effectively prevent molten iron from flowing into the slag pot, Causing local high temperature damage to the slag pot.

Slag pot spraying technology

1. The implementation of slag pot spraying technology can effectively eliminate the smoke pollution of steel slag turning over the tank

2. The implementation of slag pot spraying technology can increase the removal rate of slag tanks and facilitate the turnover of slag pot

3. The implementation of slag pot spraying technology can reduce the loss of slag pot

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Metallurgical Consumable Category

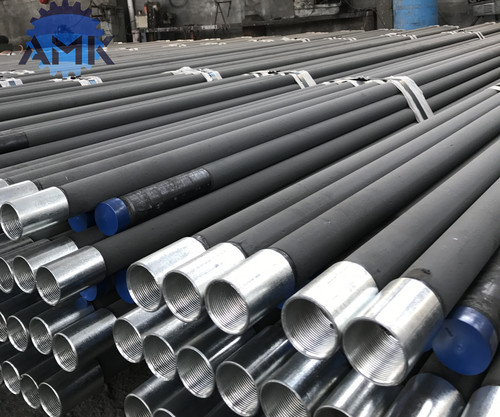

Eaf Ceramic Coated And Calorized Oxygen Lance Pipe

Price 10 USD ($) / Piece

Minimum Order Quantity : 100 Pieces

Material : Mild Steel with Ceramic Coating and Calorized Layer

Used For : Oxygen Blowing, Decarburization, Bottom Stirring

Application : Electric Arc Furnace (EAF) Steelmaking, Foundries, Metallurgical Industries

Properties : High Thermal Resistance, AntiOxidation, AntiCorrosion

Molten Steel Sampler

Price 1-2 USD ($) / Piece

Minimum Order Quantity : 1000 Pieces

Material : Paper tube with heatresistant probe

Used For : Collecting molten steel samples

Application : Steel mills, foundries, steelmaking process

Properties : Rapid and accurate steel sampling

Expendable Thermocouple

Price 1 USD ($) / Piece

Minimum Order Quantity : 100 Pieces

Material : HighQuality Quartz or Ceramic Paper Tube

Used For : Steel Foundries, Iron Casting, Ferrous/NonFerrous Metallurgy

Application : Molten Metal Temperature Measurement

Properties : High Accuracy, Rapid Response, Disposable

Ingot Mould

Price 10000 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Material : Cast Iron

Used For : Metal Ingot Formation

Application : For Melting and Casting Metals

Properties : High Durability, Strong Thermal Conductivity, Crack Resistant