Thermal Lance Pipe

Thermal Lance Pipe Specification

- Operating Temperature

- Up to 4000C

- Automation Grade

- Manual

- Pressure Ratings

- Depends on Oxygen Supply, Typically up to 10 bar

- Features

- Quick Ignition, Efficient Heat Transfer, High Cutting Speed

- Surface Treatment

- Anti-corrosive Coating

- Used For

- Demolition/Heavy Cutting Operations

- Power Source

- Oxygen Supply

- Material

- Steel

- Style

- Straight Hollow Tube

- Properties

- High Heat Resistance, Excellent Thermal Conductivity

- Capacity

- Custom Sizes Available

- Power

- Requires External Oxygen Supply

- Condition

- New

- Application

- Cutting, Boring, Melting of Metals and Concrete

Thermal Lance Pipe Trade Information

- Minimum Order Quantity

- 100 Pieces

- FOB Port

- Shanghai

- Supply Ability

- 30000 Pieces Per Year

- Delivery Time

- 1 Months

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard export package

- Main Export Market(s)

- Eastern Europe, Middle East, Africa, Central America, Western Europe, Australia, North America, South America, Asia

- Main Domestic Market

- All India

About Thermal Lance Pipe

Thermal Lance Pipe

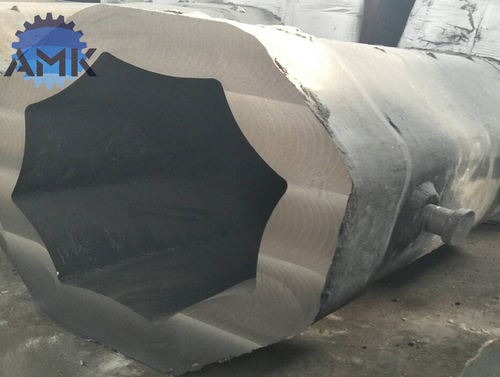

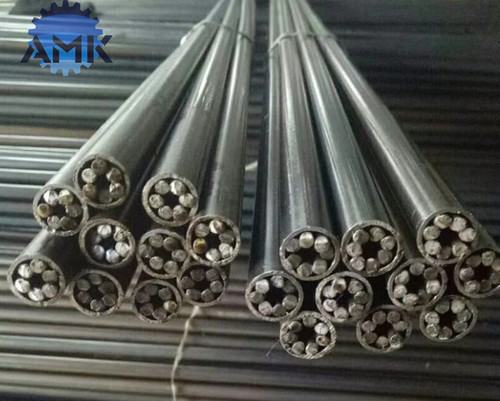

Thermallance also named thermic lance, oxygen lance, cutting lance or burning bar,etc. It creates a high temperature at least 3600 when burned along with oxygen.

The far end of the tube is pre-heated and lit by an oxyacetylene torch. An intense stream of burning steel is produced at the work piece end and can be used to cut rapidly through thick materials including steel and concrete. The tube is consumed, so every few minutes the operator shuts off the oxygen, discards the remaining stub of a lance tube and starts using a new one.

Application:Fusion cutting ,clean up or boring of all kinds of alloy casting, stainless steel casting, iron and steel casting, non-ferrous casting, concrete, rock,slag, refractory, etc.

Characteristics:

1. High efficiency

2. Easy operation

3. Multi-usages

4. Cost effective

Unmatched Cutting Efficiency

Designed for rapid and efficient heat transfer, the Thermal Lance Pipe ensures precise and quick cutting, boring, or melting of metals and concrete in demolition projects. The pipes steel construction and high thermal conductivity enable operations at extreme temperatures, maximizing productivity for industrial users.

Built for Heavy-Duty Operations

This products robust steel material, rust-proof smooth finish, and anti-corrosive surface treatment guarantee long shelf life and reliable performance. It is suitable for a wide range of harsh environments, making it a preferred option for large-scale cutting and demolition jobs globally.

FAQs of Thermal Lance Pipe:

Q: How does the Thermal Lance Pipe work during cutting and demolition operations?

A: The Thermal Lance Pipe utilizes a manual ignition method with a high-temperature source and requires an external oxygen supply to reach temperatures up to 4000C. When ignited, the oxygen reacts with the steel tube and inner filling, generating immense heat for efficient cutting and boring through tough materials like metals and concrete.Q: What are the maintenance and storage requirements for the Thermal Lance Pipe?

A: To maintain indefinite shelf life, store the Thermal Lance Pipes in a dry, covered area away from moisture and corrosive chemicals. Due to the anti-corrosive and rust-proof finish, minimal maintenance is required besides ensuring the pipes are kept clean and bundled as per storage recommendations.Q: Where is the Thermal Lance Pipe most commonly used?

A: Thermal Lance Pipes are widely utilized in demolition sites, heavy machinery maintenance, mining operations, steelworks, and construction projects where rapid, deep cutting or boring through metal or concrete is required.Q: What is the process for igniting and operating the Thermal Lance Pipe?

A: To operate, attach the pipe to an external oxygen supply, set the oxygen pressure as specified, and use a high-temperature source for manual ignition at one end of the pipe. Once ignited, the pipe rapidly heats up and can be applied directly to the material for cutting or boring.Q: What are the advantages of using this Thermal Lance Pipe over conventional methods?

A: The main benefits include significantly faster cutting speeds, the ability to handle extremely hard materials, and reliable performance even in challenging environments, thanks to its high heat resistance, smooth finish, and efficient heat transfer design.Q: What sizes and customization options are available for the Thermal Lance Pipe?

A: The pipes come in lengths of 1m to 3m, outer diameters from 8mm to 18mm, and inner diameters between 4mm to 12mm. Custom sizes can be fabricated as per client requirements, ensuring optimal fit and efficiency for different applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Metallurgical Consumable Category

Molten Steel Sampler

Price 1-2 USD ($) / Piece

Minimum Order Quantity : 1000 Pieces

Material : Paper tube with heatresistant probe

Condition : New

Style : Handheld insertion

Used For : Collecting molten steel samples

Expendable Thermocouple

Price 1 USD ($) / Piece

Minimum Order Quantity : 100 Pieces

Material : HighQuality Quartz or Ceramic Paper Tube

Condition : New

Style : Straight, Angled, or MultiDip Designs

Used For : Steel Foundries, Iron Casting, Ferrous/NonFerrous Metallurgy

Ingot Mould

Price 10000 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Material : Cast Iron

Condition : New

Style : Rectangular

Used For : Metal Ingot Formation

Slag Pot

Price 15000 USD ($) / Set

Minimum Order Quantity : 1 Set

Material : Cast Iron and Steel

Condition : New