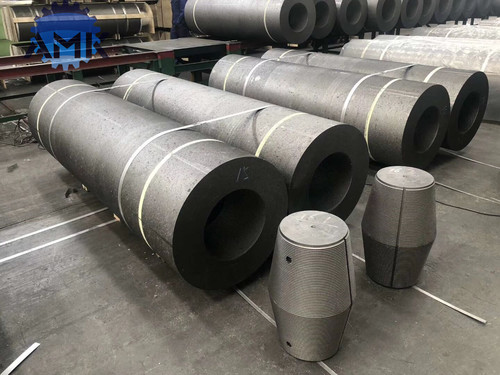

Graphite Rotor

Graphite Rotor Specification

- Load Capacity

- Varies by dimension and application

- Features

- Lightweight, precision balanced, high durability

- Automation Grade

- Manual/Automatic

- Power Source

- Manual or mechanical drive

- Used For

- Degassing and stirring in foundry industry

- Surface Treatment

- Antioxidation coated

- Operating Temperature

- Up to 1600C

- Material

- High Purity Graphite

- Style

- Rotor

- Properties

- High thermal conductivity, corrosion resistance, oxidation resistance

- Capacity

- Customizable as per requirement

- Condition

- New

- Application

- Aluminum and non-ferrous metal melting

- Porosity

- Low, <10%

- Dimension

- Customized as per requirement

- Shape

- Customizable

- Carbon Content

- >99%

- Color

- Black Gray

- Flexural Strength

- 40 MPa

- Compressive Strength

- 70 MPa

- Impurity Content

- Minimal, as per industrial standards

- Density

- 1.72 - 1.85 g/cm

- Life Span

- Long service life under proper conditions

- Ash Content

- 0.1%

Graphite Rotor Trade Information

- Minimum Order Quantity

- 10 Pieces

- FOB Port

- Shanghai

- Supply Ability

- 30000 Pieces Per Year

- Delivery Time

- 30 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden cases

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Graphite Rotor

Graphite Rotor For Aluminium Manufacturers

1.Thermal stability: special design to ensure the quality

2.Corrosion resistance: Even and fine matrix to postpone the corrosion

3.Impact resistance

4.Acid resistance : add special material to prolong the performance life

5.High thermal conductivity

6.No pollution to the metal: strict control to the raw material

7.Stable quality

Tailored for Demanding Foundry Operations

Our graphite rotor is meticulously designed for the intensive environments of aluminum and non-ferrous metal melting. With its customizable dimensions and minimal impurity content, it adapts easily to varied industrial requirements, delivering consistent performance and reliability where precision is paramount.

Built to Endure Extreme Conditions

Manufactured from high-purity graphite, this rotor boasts low porosity and exceptional resistance to corrosion and oxidation. The addition of an antioxidation coating extends its operational longevity, making it the preferred solution for high-temperature applications up to 1600C in foundries worldwide.

FAQs of Graphite Rotor:

Q: How does the graphite rotor contribute to the degassing and stirring process in foundry applications?

A: The graphite rotor efficiently promotes uniform mixing and removes dissolved gases from molten aluminum and other non-ferrous metals. Its precision-balanced design enhances the effectiveness of degassing and stirring, resulting in higher casting quality and reduced defects.Q: What is the benefit of using high-purity graphite with low porosity for rotors in metal melting?

A: High-purity graphite with low porosity ensures excellent thermal conductivity and structural integrity. This composition minimizes oxidation and chemical reactions with molten metals, extending the rotors service life while maintaining performance in harsh environments.Q: Where can this graphite rotor be used within the foundry industry?

A: This graphite rotor is suitable for aluminum and other non-ferrous metal melting facilities, specifically for degassing and stirring operations during casting. Its customizable design allows it to accommodate various furnace sizes and process requirements.Q: What is the typical process for installing and operating the graphite rotor?

A: Installation involves fitting the custom-shaped rotor onto a drive mechanism, which can be manual or mechanical. The rotor is then lowered into molten metal, where it is rotated at controlled speeds to regulate mixing and degassing, following the foundrys operating procedures.Q: When should the graphite rotor be replaced to ensure optimal performance?

A: Replacement is recommended once signs of excessive wear, deformation, or significant material loss are observed. Under proper operating conditions and with regular maintenance, the rotor offers a long service life, reducing the frequency of changeovers.Q: What makes antioxidation coating important for this graphite rotor?

A: The antioxidation coating protects the rotor from rapid oxidation at high temperatures, preserving its structural and chemical stability. This feature is essential for applications involving prolonged exposure to molten metals and high heat, significantly enhancing product durability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

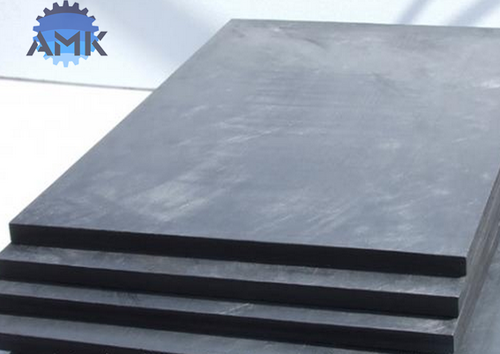

More Products in Graphite Products Category

Graphite Electrode

Price 3000.00 USD ($) / Ton

Minimum Order Quantity : 20 Tons

Used For : Steel making

Application : EAF, LF

Material : carbon, CPC, needle coke

Condition : New

Graphite Vessel

Price 1000 USD ($)

Minimum Order Quantity : 1 Piece

Used For : Storage and Reaction of Corrosive Chemicals

Application : Chemical Processing, Pharmaceutical, Petrochemical Industries

Material : High Purity Graphite

Condition : New

Graphite Container

Price 5000 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Used For : Holding and Melting Metals, HighTemperature Applications

Application : Industrial Furnace, Laboratory Use, Metal Melting

Material : High Purity Graphite

Condition : New

Carbon And Graphite Felt

Price 1000 USD ($)

Minimum Order Quantity : 2 Pieces

Used For : Heat insulation, energy storage systems

Application : Thermal insulation, vacuum furnaces, hightemperature filtration

Material : Carbon and Graphite Felt

Condition : New