Carbon And Graphite Felt

Carbon And Graphite Felt Specification

- Used For

- Heat insulation, energy storage systems

- Surface Treatment

- Uncoated/As manufactured

- Operating Temperature

- Up to 3000C (in inert atmosphere)

- Features

- Flexible, corrosion resistant, lightweight, low thermal conductivity

- Automation Grade

- Manual

- Material

- Carbon and Graphite Felt

- Style

- Roll

- Properties

- High temperature resistance, chemical stability, lightweight

- Capacity

- Customizable

- Condition

- New

- Application

- Thermal insulation, vacuum furnaces, high-temperature filtration

Carbon And Graphite Felt Trade Information

- Minimum Order Quantity

- 2 Pieces

- FOB Port

- Shanghai

- Delivery Time

- 30 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Carbon And Graphite Felt

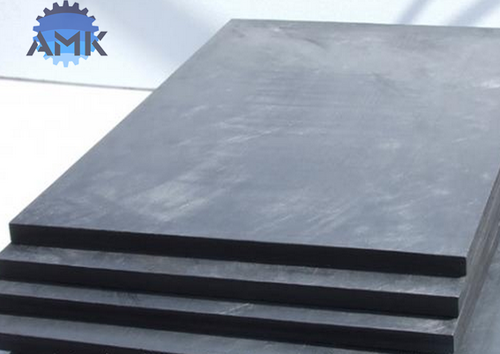

Carbon And Graphite Felt

Carbonand graphite felt is an insulating material manufactured by carbonization of natural and synthetic fibers with unique textile, chemical and thermal properties. Rigid graphite felt is a shape-retentive insulating material made from graphite fibers and a carbon binder.

Typical Applications

Furnace resistance or induction heated vacuum furnaces and inert gas furnaces, such as degassing furnace, brazing furnaces, soft and bright annealing furnaces, sintering furnaces for hard metals, carburizing furnaces, laboratory graphitizing furnaces; inductively heated melting and heat treatment furnace, in which aproportion of the ceramic insulting material is replaced by felt in order to increase the electrical efficiency and prevent the liquid metal from coming into contact with the induction coil in the event of crucible fracture (not wetting).

Engineered for Extreme Environments

Carbon and graphite felt is designed to perform reliably in high-temperature settings such as vacuum furnaces and energy storage systems. Its excellent resistance to heat and chemicals makes it a superior choice for industries demanding advanced thermal insulation solutions. With customizable thickness and dimensions, it suits an array of specialized requirements.

Quality and Versatility in Every Sheet

Manufactured with high purity and low ash content, this felt ensures minimal contamination and reliable performance. Its flexibility and lightweight nature make it easy to install, handle, and shape as needed, while its corrosion resistance guarantees longevity even in harsh conditions.

FAQs of Carbon And Graphite Felt:

Q: How is carbon and graphite felt typically used in industrial applications?

A: Carbon and graphite felt is primarily used for thermal insulation, high-temperature filtration, and in vacuum furnaces. Its ability to withstand temperatures up to 3000C in an inert atmosphere makes it ideal for heat insulation and energy storage systems.Q: What customization options are available for thickness and width?

A: The felt can be customized in thickness from 3 mm to 20 mm and widths are common up to 1.2 meters. Special requests for other dimensions can be accommodated to fit specific project requirements.Q: When should carbon and graphite felt be replaced or inspected during use?

A: It is advisable to inspect the felt regularly, especially in high-heat or chemically aggressive environments. Replacement is generally considered when there are signs of physical degradation or reduced insulating performance, although its durability is high when kept dry and properly installed.Q: Where is this material most commonly applied?

A: Carbon and graphite felt is widely applied in sectors requiring advanced heat management, such as furnace manufacturing, metallurgical processing, energy storage, and filtration systems.Q: What are the main benefits of using carbon and graphite felt?

A: The felt offers high-temperature resistance, chemical stability, lightweight construction, low thermal conductivity, and customizable sizing, making it both efficient and adaptable for various industrial uses.Q: How is the carbon and graphite felt packaged for shipment?

A: The material is supplied in roll or sheet form and packed in protective wrapping to safeguard against moisture and contamination during transit and storage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Graphite Products Category

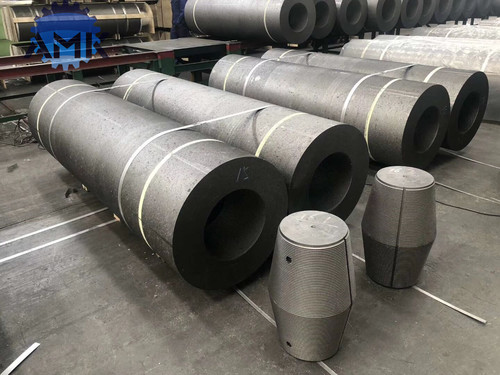

Graphite Electrode

Price 3000.00 USD ($) / Ton

Minimum Order Quantity : 20 Tons

Used For : Steel making

Material : carbon, CPC, needle coke

Application : EAF, LF

Capacity : 100 tons Ton/day

Graphite Rotor

Price 50 USD ($)

Minimum Order Quantity : 10 Pieces

Used For : Degassing and stirring in foundry industry

Material : High Purity Graphite

Application : Aluminum and nonferrous metal melting

Capacity : Customizable as per requirement

Graphite Container

Price 5000 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Used For : Holding and Melting Metals, HighTemperature Applications

Material : High Purity Graphite

Application : Industrial Furnace, Laboratory Use, Metal Melting

Capacity : Customizable

Graphite Crucible

Price 5000 USD ($) / Piece

Minimum Order Quantity : 2 Pieces

Used For : Gold, Silver, Copper, Brass, Aluminum melting

Material : High Purity Graphite

Application : Melting, Casting and Refining Metals

Capacity : 1 kg to 8 kg