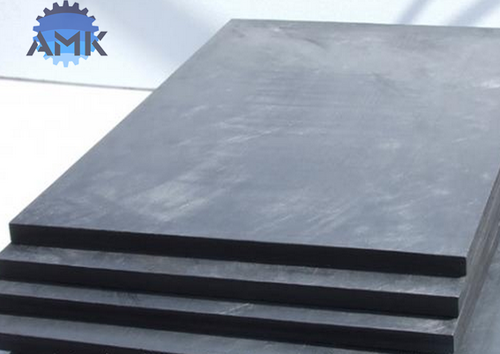

Graphite Container

Graphite Container Specification

- Surface Treatment

- Machined Finish

- Features

- Excellent Thermal Conductivity, Robust Structure, Corrosion Resistant

- Automation Grade

- Manual

- Operating Temperature

- Up to 3000C

- Used For

- Holding and Melting Metals, High-Temperature Applications

- Load Capacity

- Depends on Size

- Material

- High Purity Graphite

- Style

- Rectangular/Square Shape

- Properties

- High Thermal Resistance, Chemical Inertness

- Capacity

- Customizable

- Condition

- New

- Application

- Industrial Furnace, Laboratory Use, Metal Melting

- Shape

- Box/Container

- Dimensions

- Customizable as per Requirement

- Ash Content

- 0.1%

- Thermal Expansion Coefficient

- 4.910/K

- Hardness

- 50-60 HSD

- Density

- 1.65-1.85 g/cm

- Resistivity

- 8-15 m

- OEM Service

- Available

- Water Absorption

- Negligible

- Porosity

- Low

- Color

- Black

Graphite Container Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Shanghai

- Supply Ability

- 30000 Pieces Per Year

- Delivery Time

- 25 Days

- Packaging Details

- wooden case

- Main Export Market(s)

- Western Europe, Africa, South America, Australia, Middle East, Eastern Europe, Central America, Asia, North America

- Main Domestic Market

- All India

About Graphite Container

Graphite Container

AMK Supply List:

|

Group no.1 |

Continuous Casting Related |

|

1 |

Copper Mould Tube |

|

2 |

Copper Mould Plate |

|

3 |

Mould Assembly & Fittings |

|

4 |

Cooling Water Jacket |

|

5 |

Spray Nozzles & Spare parts |

|

6 |

Continuous Caster Spare Parts |

|

7 |

Torch Cutting Machine |

|

8 |

Hydraulic Cylinder |

|

Group no.2 |

Metallurgical consumables |

|

1 |

Oxygen lance pipes |

|

2 |

Thermal cutting lance |

|

3 |

Molten steel sampler |

|

4 |

Expendable thermocouple |

|

5 |

Slag pot |

|

Group no.3 |

Rolling Mill Related |

|

1 |

Cast iron&steel rolls |

|

2 |

Forged steel rolls |

|

3 |

Tungsten carbide roll rilng |

|

4 |

Bearing products |

|

Group no.4 |

Graphite products |

|

1 |

Graphite Crucible |

|

2 |

Graphite electrode |

|

3 |

Graphite Spare Parts |

|

4 |

Magnesia carbon brick |

|

Group no.5 |

Stainless Steel Products |

|

1 |

Stainless Steel Sheet & Coil |

|

2 |

Stainless Steel Products |

|

Group no.6 |

Others |

|

1 |

Flanges and pipe fittings |

|

2 |

Electric motor |

|

|

|

Engineered for High-Temperature Demands

These graphite containers stand out for their ability to operate at temperatures reaching 3000C, making them ideal for tasks like industrial furnace processes, laboratory work, and metal melting. The low porosity and high density enhance their resilience and thermal conductivity, ensuring they withstand demanding environments without compromise.

Precision Tailored to Your Needs

Every container is produced to precise, customizable dimensions and capacities, supported by an OEM service focused on fulfilling specialized requirements. Whether your operations need a rectangular or square box for holding or melting various metals, our team delivers a solution with meticulous machining and surface treatment.

Outstanding Performance and Reliability

The containers provide a combination of mechanical strength (50-60 HSD hardness), excellent chemical inertness, and corrosion resistance. Their low water absorption and minimal ash content guarantee clean performance, while the robust design ensures longevity and safety in repeated high-temperature cycles.

FAQs of Graphite Container:

Q: How are these graphite containers used in metal melting and laboratory applications?

A: These containers are designed to hold and melt metals at elevated temperatures, up to 3000C. Their high thermal resistance and chemical inertness make them suitable for laboratory and industrial furnace environments, ensuring contained materials experience uniform heating and minimal contamination during critical processes.Q: What are the benefits of choosing high-purity graphite for these containers?

A: High-purity graphite offers superior thermal conductivity, low ash content (0.1%), and exceptional chemical stability. This ensures minimal reactivity with contents, improved lifespan in harsh conditions, and reduced risk of impurities contaminating your metals or experiments.Q: What customization options are available for size and capacity?

A: We provide OEM services to tailor the containers dimensions and capacity according to your specific requirements. Whether you require a particular box size, shape (rectangular or square), or volume, our production process ensures your needs are accurately met.Q: When should I opt for a machined finish on the graphite container?

A: A machined finish is ideal when precise dimensions and smooth surfaces are essential, helping ensure better fit within equipment and easier handling. Machining also provides a cleaner, more uniform appearance, which can be important in research and high-precision melting tasks.Q: What process is used to achieve low porosity and high durability in these containers?

A: The containers are manufactured using advanced technologies that compress high-purity graphite to a dense state (1.65-1.85 g/cm) and minimize porosity. This process enhances structural strength and limits gas or liquid penetration, improving durability in high-temperature, corrosive, or demanding environments.Q: Where can these graphite containers be sourced or used globally?

A: We serve as a global distributor, exporter, manufacturer, and supplier with a strong presence in China. Our products support industrial and laboratory operations worldwide, meeting stringent international quality standards.Q: What are the key features that enhance operational efficiency with these containers?

A: The containers offer excellent thermal conductivity, robust structure, corrosion resistance, and negligible water absorption. These features reduce process downtime, support reliable metal melting and handling, and ensure the container remains safe and effective through repeated cycles.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Graphite Products Category

Graphite Rotor

Price 50 USD ($)

Minimum Order Quantity : 10 Pieces

Application : Aluminum and nonferrous metal melting

Used For : Degassing and stirring in foundry industry

Material : High Purity Graphite

Condition : New

Graphite Stopper

Price 100 USD ($)

Minimum Order Quantity : 10 Pieces

Application : Industrial crucibles, Foundries, Metallurgical processes

Used For : Controlling flow of molten metal in crucibles

Material : High Purity Graphite

Condition : New

Graphite Vessel

Price 1000 USD ($)

Minimum Order Quantity : 1 Piece

Application : Chemical Processing, Pharmaceutical, Petrochemical Industries

Used For : Storage and Reaction of Corrosive Chemicals

Material : High Purity Graphite

Condition : New

Carbon And Graphite Felt

Price 1000 USD ($)

Minimum Order Quantity : 2 Pieces

Application : Thermal insulation, vacuum furnaces, hightemperature filtration

Used For : Heat insulation, energy storage systems

Material : Carbon and Graphite Felt

Condition : New