Graphite Vessel

Graphite Vessel Specification

- Automation Grade

- Manual

- Surface Treatment

- Polished

- Used For

- Storage and Reaction of Corrosive Chemicals

- Load Capacity

- Up to 500 kg

- Operating Temperature

- Up to 2200C

- Features

- Leak Proof Design, High Strength, Precision Machining

- Pressure Ratings

- Up to 10 bar

- Material

- High Purity Graphite

- Style

- Cylindrical Vessel

- Properties

- High Thermal Conductivity, Noncorrosive, Chemical Resistance

- Capacity

- 100 Liters (Customizable)

- Power

- Not Applicable (No Power Required)

- Condition

- New

- Application

- Chemical Processing, Pharmaceutical, Petrochemical Industries

Graphite Vessel Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Shanghai

- Payment Terms

- Cash Against Delivery (CAD), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cash in Advance (CID)

- Delivery Time

- 30 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Graphite Vessel

Graphite Vessel|

Group no.1 |

Continuous Casting Related |

|

1 |

Copper Mould Tube |

|

2 |

Copper Mould Plate |

|

3 |

Mould Assembly & Fittings |

|

4 |

Cooling Water Jacket |

|

5 |

Spray Nozzles & Spare parts |

|

6 |

Continuous Caster Spare Parts |

|

7 |

Torch Cutting Machine |

|

8 |

Hydraulic Cylinder |

|

Group no.2 |

Metallurgical consumables |

|

1 |

Oxygen lance pipes |

|

2 |

Thermal cutting lance |

|

3 |

Molten steel sampler |

|

4 |

Expendable thermocouple |

|

5 |

Slag pot |

|

Group no.3 |

Rolling Mill Related |

|

1 |

Cast iron&steel rolls |

|

2 |

Forged steel rolls |

|

3 |

Tungsten carbide roll rilng |

|

4 |

Bearing products |

|

Group no.4 |

Graphite products |

|

1 |

Graphite Crucible |

|

2 |

Graphite electrode |

|

3 |

Graphite Spare Parts |

|

4 |

Magnesia carbon brick |

|

Group no.5 |

Stainless Steel Products |

|

1 |

Stainless Steel Sheet & Coil |

|

2 |

Stainless Steel Products |

|

Group no.6 |

Others |

|

1 |

Flanges and pipe fittings |

|

2 |

Electric motor |

|

|

|

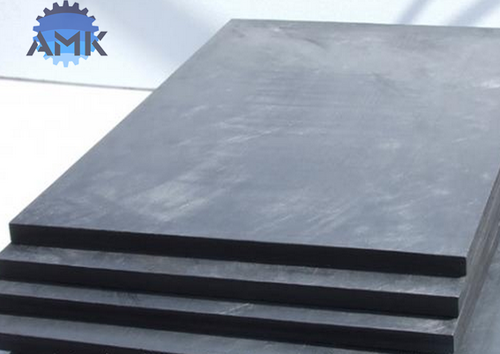

Designed for High-Performance Applications

The graphite vessels robust structure and use of high purity graphite ensure reliable performance under extreme conditions. With a chemical-resistant, noncorrosive finish, this vessel is suitable for handling aggressive chemicals, reacting compounds, and ensuring safety in sensitive applications across multiple industries.

Customizable and Versatile Connection Options

Offering both threaded and flanged port connections, this vessel adapts seamlessly to diverse processing setups. The bolted flange cover ensures secure, leak-free sealing, while its cylindrical style and customizable capacity provide adaptability for various operational requirements.

Safe Operation and Easy Maintenance

With manual automation grade and a leak-proof, polished design, routine maintenance is simplified and safety enhanced. The absence of power requirements reduces complexity and cost, while high thermal conductivity and load ratings guarantee stability during high-temperature processes.

FAQs of Graphite Vessel:

Q: How is the graphite vessel typically used in industrial settings?

A: This vessel is commonly used for the storage and reaction of corrosive chemicals in chemical processing, pharmaceutical, and petrochemical industries due to its chemical resistance and high thermal conductivity.Q: What benefits does the high purity graphite material provide?

A: High purity graphite offers exceptional chemical resistance, noncorrosive properties, high tensile strength, and the ability to withstand high temperatures up to 2200C, ensuring vessel durability and safety.Q: When should threaded or flanged port connections be selected?

A: Threaded or flanged port connections are chosen based on process compatibility and installation needs. Flanged connections are ideal for secure, high-pressure environments, whereas threaded ports offer straightforward, versatile connections.Q: Where can this vessel be installed?

A: The vessel is suitable for installation in laboratories, production plants, and industrial facilities handling corrosive or high-temperature chemical processes across chemical, pharmaceutical, and petrochemical sectors.Q: What makes the vessel design leak proof and safe?

A: The precision-machined body and bolted flange cover provide a secure seal, while the high-quality polished surface and robust material offer leak-proof performance, ensuring operational safety.Q: How customizable is the vessel capacity?

A: While the standard capacity is 100 liters, customization options are available to suit specific process requirements, allowing flexibility for diverse operational needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Graphite Products Category

Graphite Rotor

Price 50 USD ($)

Minimum Order Quantity : 10 Pieces

Material : High Purity Graphite

Application : Aluminum and nonferrous metal melting

Used For : Degassing and stirring in foundry industry

Operating Temperature : Up to 1600C

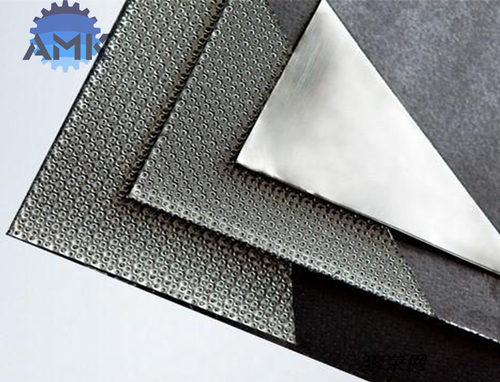

Reinforced Graphite Sheet

Price 100 USD ($)

Minimum Order Quantity : 5 Pieces

Material : Reinforced Graphite

Application : Gasketing, sealing, hightemperature and highpressure environments

Used For : Flange sealing, pipe and vessel gaskets, engine gaskets

Operating Temperature : 200C to +550C (depending on specific reinforcement and application)

Graphite Stopper

Price 100 USD ($)

Minimum Order Quantity : 10 Pieces

Material : High Purity Graphite

Application : Industrial crucibles, Foundries, Metallurgical processes

Used For : Controlling flow of molten metal in crucibles

Operating Temperature : Up to 3000C

Carbon And Graphite Felt

Price 1000 USD ($)

Minimum Order Quantity : 2 Pieces

Material : Carbon and Graphite Felt

Application : Thermal insulation, vacuum furnaces, hightemperature filtration

Used For : Heat insulation, energy storage systems

Operating Temperature : Up to 3000C (in inert atmosphere)