Graphite Crucible

Graphite Crucible Specification

- Automation Grade

- Manual

- Used For

- Gold, Silver, Copper, Brass, Aluminum melting

- Operating Temperature

- Up to 1600C

- Power Source

- Furnace

- Features

- Acid and Alkali resistance, Durable, Eco-friendly

- Load Capacity

- Varies by model

- Surface Treatment

- Smooth Finish

- Material

- High Purity Graphite

- Style

- Cylindrical

- Properties

- High thermal conductivity, corrosion resistance

- Capacity

- 1 kg to 8 kg

- Condition

- New

- Application

- Melting, Casting and Refining Metals

- Color

- Black / Dark Gray

- Ash Content

- 0.1%

- Shape

- Round

- Lid Included

- No

- Melting Point

- Over 3000C

- Thermal Shock Resistance

- Excellent

- Hardness

- Shore Hardness 45-55

- Density

- 1.80 1.85 g/cm

Graphite Crucible Trade Information

- Minimum Order Quantity

- 2 Pieces

- FOB Port

- Shanghai

- Delivery Time

- 25 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Graphite Crucible

Graphite Crucible

We supply standard graphite crucibles as well as high density graphite crucibles.

Bulk density of standard graphite crucible: Min.1.72 g/cm3

Bulk density of high purity graphite crucible: Min.1.8 g/cm3

We also provide clay graphite crucibles and silicon carbide graphite crucibles.

We can manufacture standard and non-standard graphite crucibles according to your demands.

We supply graphite crucibles as big as Dia.136x35 CM, which is used for our American customer.

Exceptional Material Durability

Manufactured from high-purity graphite, this crucible is engineered to withstand extreme temperatures beyond 3000C, offering high resistance to corrosion, acids, and alkalis. Its robust design and manual operation make it ideal for both professional and industrial applications where consistent performance is required.

Versatile Metal Melting Applications

Tailored for the efficient melting, casting, and refining of precious and non-precious metals, the crucible is suitable for gold, silver, copper, brass, and aluminum. Its excellent thermal shock resistance and smooth surface treatment ensure optimal results and easy release of molten metals.

FAQs of Graphite Crucible:

Q: How should the graphite crucible be used during metal melting and casting?

A: Place the required amount of metal into the crucible and position it securely inside a compatible furnace. Gradually heat the setup to the desired temperature, ensuring it does not exceed the crucibles recommended operating temperature of 1600C. Handle carefully to avoid thermal shock and prolong crucible life.Q: What are the key benefits of using a high-purity graphite crucible for melting metals?

A: High-purity graphite crucibles offer superior thermal conductivity, minimal ash contamination (0.1%), excellent resistance to acids and alkalis, and robust durability. These properties help achieve uniform heating, protect the integrity of your metals, and ensure a clean, eco-friendly process.Q: When should I replace a graphite crucible?

A: Replace the crucible if you notice significant wear, cracks, or contamination affecting its performance. Lifespan varies depending on usage frequency, metal types, and adherence to recommended operational procedures, but regular inspection is suggested before each use.Q: Where can this graphite crucible be used effectively?

A: This crucible is well-suited for foundries, jewelry workshops, laboratories, and other industrial settings requiring efficient melting, casting, or refining of metals. It is supplied by trusted distributors, exporters, manufacturers, suppliers, and traders based in China.Q: What is the process for cleaning the crucible after use?

A: After use, allow the crucible to cool slowly to room temperature. Once cool, gently remove residual metal and debris with a soft brush or scraper. Avoid using water or harsh chemicals. Store the crucible in a dry location to preserve its properties and longevity.Q: Is the crucible environmentally friendly and safe to use?

A: Yes, made with high-purity graphite and designed for low ash output and high durability, the crucible is eco-friendly. It emits minimal contaminants, and its solid construction minimizes the need for frequent replacement, reducing waste in the long term.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Graphite Products Category

Graphite Ring

Price 50 USD ($)

Minimum Order Quantity : 10 Pieces

Application : Sealing in valves, pumps, chemical and petrochemical industries

Material : Pure Graphite

Automation Grade : Manual

Condition : New

Graphite Container

Price 5000 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Application : Industrial Furnace, Laboratory Use, Metal Melting

Material : High Purity Graphite

Automation Grade : Manual

Condition : New

Graphite Stopper

Price 100 USD ($)

Minimum Order Quantity : 10 Pieces

Application : Industrial crucibles, Foundries, Metallurgical processes

Material : High Purity Graphite

Automation Grade : Manual

Condition : New

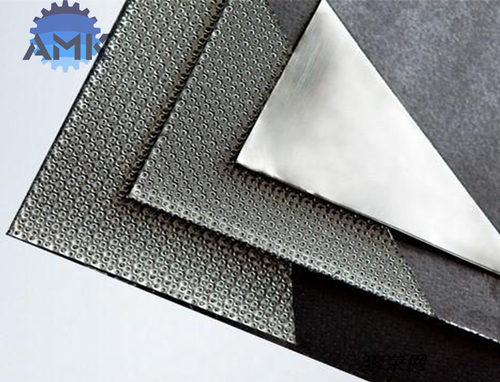

Reinforced Graphite Sheet

Price 100 USD ($)

Minimum Order Quantity : 5 Pieces

Application : Gasketing, sealing, hightemperature and highpressure environments

Material : Reinforced Graphite

Automation Grade : Manual

Condition : New