Ccm Straightener

Ccm Straightener Specification

- Usage & Applications

- Steel Plant, Used for Straightening Cast Metal Bars & Billets

- Casting Process

- Continuous Casting

- Load Capacity

- 20 Ton

- Product Type

- CCM Straightener

- Material

- Mild Steel

- Surface Finishing

- Paint Coated

- Weight

- 5000 Kilograms (kg)

- Color

- Blue

Ccm Straightener Trade Information

- Minimum Order Quantity

- 2 Pieces

- FOB Port

- Shanghai

- Supply Ability

- 20000 Pieces Per Month

- Delivery Time

- 30 Days

- Packaging Details

- wooden cases

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Ccm Straightener

Experience the new release Ccm Straightener, a featured, ace solution engineered for billet and bloom continuous casting machines. Designed for flawless performance, this machine boasts robust construction for high durability and effortless maintenance. The lofty automation includes an electric power source operating at 415 Volt with 10 precision rollers and adjustable working speed. With an operating temperature up to 600C and a load capacity of 20 tons, this limited-time offering efficiently straightens cast metal bars and billets. Its paint-coated finish on ductile iron and mild steel ensures lasting reliability and appeal for steel plants.

Special Features and Application Advantages

The Ccm Straightener offers automatic operation powered by electricity for consistent, stable results. Adjustable working speed enables optimal straightening for various billet and bloom sizes. The robust paint-coated surface resists wear and corrosion, ensuring longevity. Easy maintenance coupled with high load capacity makes it suitable for demanding steel plant environments. The application method is streamlinedsimply feed cast metal bars or billets into the rollers for flawless straightening, enhancing productivity.

Domestic and Export Markets: Fast Dispatch and Secure Freight

We serve the main domestic market across China and offer quick dispatch services to ensure timely order processing. Our FOB port ensures seamless logistics for shipments to major export markets worldwide. Our expert distributor, exporter, manufacturer, supplier, and trader network guarantees fast, secure freight with reliable order tracking for your peace of mind. Connect with our team for efficient support and rapid delivery solutions for steel industry clients.

Special Features and Application Advantages

The Ccm Straightener offers automatic operation powered by electricity for consistent, stable results. Adjustable working speed enables optimal straightening for various billet and bloom sizes. The robust paint-coated surface resists wear and corrosion, ensuring longevity. Easy maintenance coupled with high load capacity makes it suitable for demanding steel plant environments. The application method is streamlinedsimply feed cast metal bars or billets into the rollers for flawless straightening, enhancing productivity.

Domestic and Export Markets: Fast Dispatch and Secure Freight

We serve the main domestic market across China and offer quick dispatch services to ensure timely order processing. Our FOB port ensures seamless logistics for shipments to major export markets worldwide. Our expert distributor, exporter, manufacturer, supplier, and trader network guarantees fast, secure freight with reliable order tracking for your peace of mind. Connect with our team for efficient support and rapid delivery solutions for steel industry clients.

FAQs of Ccm Straightener:

Q: How does the automatic operation of the Ccm Straightener improve workflow?

A: The automatic operation streamlines the straightening process by reducing manual intervention, allowing for consistent processing and higher efficiency within steel plants.Q: What materials can be processed with this straightener?

A: The Ccm Straightener handles ductile iron and mild steel, making it suitable for cast metal bars and billets manufactured through continuous casting.Q: Where is the primary application of the Ccm Straightener?

A: The Ccm Straightener is primarily used within steel plants, specifically for straightening billets and blooms coming from continuous casting machines.Q: What is the process of operating the straightener?

A: Simply feed the cast metal bars or billets into the machine; the 10 adjustable rollers and automated settings will straighten them efficiently at temperatures up to 600C.Q: What are the advantages of the paint-coated surface?

A: The paint-coated surface provides enhanced resistance against corrosion and wear, ensuring the machine remains durable and robust during intensive use.Q: How quickly can orders be dispatched?

A: We prioritize quick dispatch following order processing, with reliable freight options and tracking available for both domestic and international clients.Q: Why is easy maintenance important for users?

A: Easy maintenance reduces downtime, simplifies servicing, and keeps the machinery running smoothly, ensuring optimal operation and extended lifespan.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Continuous Casting Equipment Category

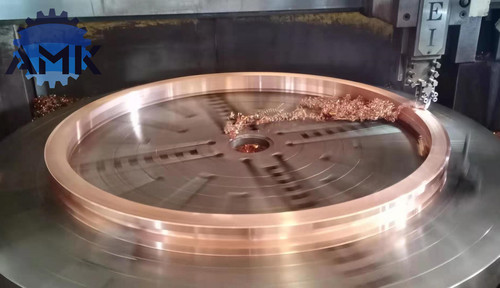

Casting Wheel

Price 5000.00 INR / Piece

Minimum Order Quantity : 50 Pieces

Material : Other Ductile Iron, Cast Iron / Mild Steel / Alloy Steel

Surface Finishing : Other, Smooth Painted / Powder Coated

Color : Black / Grey

Product Type : Cast Equipment

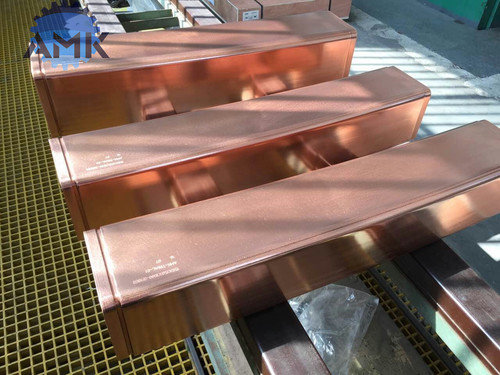

Copper Mould Tube

Price 13.00 USD ($) / Kilograms

Minimum Order Quantity : 120 Kilograms

Material : Copper

Surface Finishing : Polishing

Color : copper

Mould Assembly

Price 20000 USD ($) / Set

Minimum Order Quantity : 1 Set

Material : Stainless Steel

Surface Finishing : Painting

Product Type : Cast Equipment

Mould Assembly Spare Parts

Price 1 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel