Casting Wheel

Casting Wheel Specification

- Casting Process

- Sand Casting / Die Casting

- Usage & Applications

- Material Handling, Trolleys, Carts, Industrial Machinery

- Load Capacity

- 200-1500 kg

- Product Type

- Cast Equipment

- Material

- Cast Iron / Mild Steel / Alloy Steel

- Surface Finishing

- Smooth Painted / Powder Coated

- Weight

- 5-25 kg (Depending on size)

- Color

- Black / Grey

- Wear Resistance

- High

- Manufacturing Standard

- IS/BS/DIN Standards Compliant

- Hardness

- Brinell 180-240 HB

- Corrosion Resistance

- Yes (with suitable coatings)

- Customisation

- Available as per client requirements

- Temperature Resistance

- Up to 250°C

- Bore Size

- 20-50 mm

- Packing Type

- Wooden Crate / Carton Box

- Diameter

- 100-400 mm

Casting Wheel Trade Information

- Minimum Order Quantity

- 50 Pieces

- FOB Port

- Shanghai

- Payment Terms

- Letter of Credit at Sight (Sight L/C), Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID)

- Supply Ability

- 30000 Pieces Per Year

- Delivery Time

- 30 Days

- Packaging Details

- wooden cases

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

About Casting Wheel

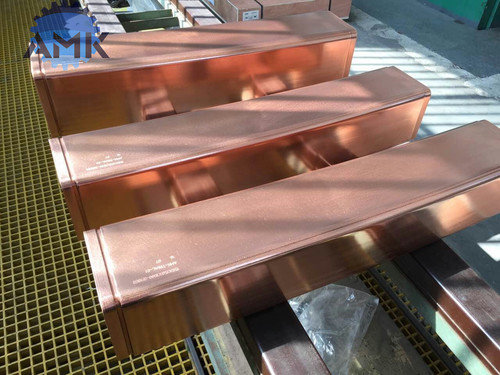

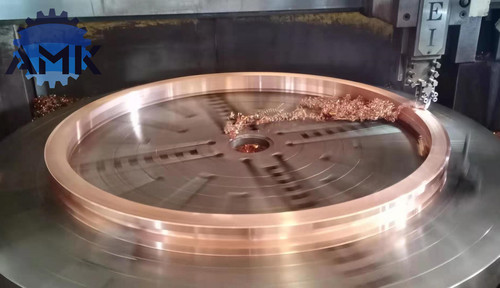

Casting Wheel

Casting wheel is designed by using sophisticated technologies under the direction of our expert professionals as per the set industrial norms. Further, these wheels are checked by our quality controllers on different quality parameters before delivering to our valued customer ends. Further, these wheels are used for various applications efficiently and quiet manner, which is available in different specifications to suit the specific demands of our esteemed customers. Our offered Casting wheel is known for their unique features like dimensional accuracy, durability and fine finishing.

Versatile Performance for Industrial Needs

Designed to tackle rigorous tasks, the casting wheel fits a wide variety of applications such as material handling, trolleys, and machinery across different industries. Its construction from robust materials ensures long service life even under heavy loads or high temperatures.

Customisation and Standards Compliance

Our casting wheels are available with extensive customization options in size, material, finish, and bore dimensions to align with unique operational demands. All products conform to international standards such as IS, BS, and DIN for assured quality and compatibility.

Durability and Safety Assurance

Brinell hardness of 180-240 HB and high wear resistance guarantee enduring performance. Enhanced with specialized coatings, the wheels resist corrosion, making them suitable for various environments. Each wheel is carefully packed in wooden crates or cartons to ensure safe delivery.

FAQs of Casting Wheel:

Q: How can I select the right diameter and bore size for my casting wheel needs?

A: Choose the diameter (100-400 mm) and bore size (20-50 mm) based on your equipments specifications, required load capacity, and application type. Our team is available to assist you with any technical considerations or custom requirements.Q: What industries typically use these casting wheels?

A: These wheels are commonly used in material handling, industrial trolleys, carts, and heavy machinery within manufacturing plants, warehouses, and distribution centers. Their robustness makes them ideal for both indoor and outdoor industrial environments.Q: When is corrosion-resistant coating recommended?

A: Corrosion-resistant coatings are essential if the casting wheels will be used in humid, corrosive, or outdoor conditions. These coatings extend the wheels lifespan by protecting the metal from deterioration over time.Q: What casting processes are used for manufacturing these wheels?

A: We utilize both sand casting and die casting methods, depending on the material, required precision, and production volume. This ensures each wheel achieves optimal structural integrity and surface finish.Q: Where can I request customization for casting wheels?

A: Customizationssuch as dimensions, materials, finish, or mounting optionscan be requested directly from our sales team. We offer tailored solutions to match your exact specifications and unique industrial needs.Q: How does the wheels hardness and temperature resistance benefit usage?

A: With a Brinell hardness of 180-240 HB and resistance to temperatures up to 250C, the wheels maintain structural integrity under treatment processes or hot material movement, ensuring durability and safety during operation.Q: What is the typical packing method for these wheels?

A: To ensure safety during transit and storage, wheels are packaged in sturdy wooden crates or carton boxes, protecting them from damage and environmental exposure.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Continuous Casting Equipment Category

Torch Cutting Machines

Price 10000 USD ($) / Set

Minimum Order Quantity : 1 Set

Material : Other Ductile Iron, Mild Steel

Surface Finishing : Polished

Product Type : Other, Torch Cutting Machine

Color : Blue & Yellow

Copper Mould Tube

Price 13.00 USD ($) / Kilograms

Minimum Order Quantity : 120 Kilograms

Material : Copper

Surface Finishing : Polishing

Color : copper

Mould Assembly

Price 20000 USD ($) / Set

Minimum Order Quantity : 1 Set

Material : Stainless Steel

Surface Finishing : Painting

Product Type : Cast Equipment

Water Jacket

Price 10000 USD ($) / Set

Minimum Order Quantity : 1 Set

Material : Stainless Steel

Surface Finishing : Polishing

Product Type : Cast Equipment