Electric Arc Furnace

Electric Arc Furnace Specification

- Feature

- Energy Efficient, Fast Melting, Automated Controls

- Rating

- Heavy Duty

- Condition

- New

- Type

- Electric Arc Furnace

- Usage

- Industrial Melting

- Power

- 3 Phase, 415V

- Voltage

- 415-440 V

- Size

- Customizable

- Dimensions

- As per requirement

- Weight

- Depends on capacity

- Application

- Steel and Alloy Melting

- Fuel Type

- Electric

- Capacity

- Up to 100 Tons

Electric Arc Furnace Trade Information

- Minimum Order Quantity

- 1 Set

- FOB Port

- Shanghai

- Supply Ability

- 2500 Sets Per Month

- Delivery Time

- 45 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Middle East, Australia, North America, Africa, Eastern Europe, Western Europe, South America, Central America, Asia

- Main Domestic Market

- All India

About Electric Arc Furnace

Electric Arc Furnace

Electric Arc Furnace (EAF)

We supply standard and customized HX series EAF.

The EAF types we can supply are not limited to the following list.

|

Type |

Nominal Capacity Unit: MT |

Transformer Capcity Unit: KVA |

Furnace Shell Diameter Unit:MM |

E;etrode Diameter Unit: MM |

Central Circle Unit:MM |

Cooling Water Consumption Unit: MT |

|

HX-5 |

5 |

3200/4000 |

3200 |

300 |

850 |

120 |

|

HX-10 |

10 |

5500/6300 |

3500 |

350 |

950 |

125 |

|

HX-15 |

15 |

7000/9000 |

3800 |

400 |

1000 |

130 |

|

HX-20 |

20 |

8000/12500 |

4200 |

400 |

1050 |

150 |

|

HX-30 |

30 |

12500/25000 |

4600 |

450 |

1150 |

180 |

|

HX-40 |

40 |

20000/31500 |

5000 |

500 |

1250 |

210 |

|

HX-50 |

50 |

25000/40000 |

5200 |

500 |

1300 |

250 |

|

HX-75 |

75 |

50000/63000 |

5800 |

550 |

1450 |

260 |

|

HX-100 |

100 |

50000/8000 |

6400 |

600 |

1450 |

280 |

High Performance Steel Shell Construction

The furnace features a robust heavy-duty steel shell, ensuring exceptional durability and longevity under intense operational conditions. The water-cooled panels provide efficient temperature control, enhancing safety and extending equipment lifespan. Customizable dimensions guarantee a perfect fit for various facility sizes and specific client requirements.

Efficient Melting with Graphite Electrodes

Utilizing graphite electrodes, the furnace achieves rapid melting times of 30-50 minutes per batch. This enables high productivity while maintaining optimal energy efficiency and consistent melt quality, making it suitable for demanding industrial environments.

Advanced Automation and User Control

Equipped with a PLC automated control panel, the system offers user-friendly operation and precise process management. Both automatic and semi-automatic modes are available, streamlining workflow and ensuring safety through real-time monitoring and diagnostics.

FAQs of Electric Arc Furnace:

Q: How is the Electric Arc Furnace installed and commissioned at an industrial site?

A: Our Electric Arc Furnace is delivered with on-site installation and commissioning support by experienced technicians. The process includes assembly, calibration, and initial testing to ensure optimal performance tailored to your facilitys requirements.Q: What is the typical process flow for melting steel or alloys using this furnace?

A: Material is charged into the furnace, followed by electrode lowering and arc initiation. With a batch melting time of 30-50 minutes, the PLC system precisely manages heating. Molten metal is then poured by tilting the furnace via hydraulic or electric mechanism.Q: When should the graphite electrodes be replaced during operation?

A: Graphite electrodes are subject to gradual wear during melting cycles and should be replaced when they reach their minimum safe length, as indicated in the furnace manual or control panel alerts, ensuring efficient and safe operation.Q: Where is the ideal application for this furnace model?

A: This model is ideal for industrial-scale steel and alloy melting, particularly in foundries, steel mills, and recycling plants looking for high-capacity and energy-efficient melting solutions.Q: What benefits does this Electric Arc Furnace provide over traditional fuel-based furnaces?

A: Operating electrically with advanced automation, it ensures rapid, consistent melting, minimizes energy consumption, and reduces emissions via the included chimney and efficient fume extraction, making it more environmentally friendly.Q: How does the water-cooled panel system enhance furnace operation?

A: The integrated water-cooled panels maintain stable shell temperatures, protecting structural integrity, reducing heat loss, and improving overall safety for both equipment and operators.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Steel Making Furnaces Category

Titanium Bearing Pellets

Price 120 USD ($) / Ton

Minimum Order Quantity : 1000 tons Tons

Application : Steel production, Alloy manufacturing, Vacuum deposition, Research

Usage : Other, Industrial, Metallurgical, Laboratory, Catalysis

Size : Custom and standard sizes available

Rating : High purity industrial grade

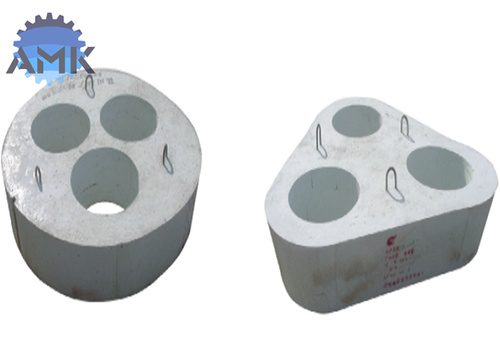

Eaf Lid

Price 3000 USD ($) / Box

Minimum Order Quantity : 2 Pieces

Application : Metallurgical industry, Electric Arc Furnaces

Usage : Other, Steel Melting/EAF Cover

Size : Customizable as per EAF design

Rating : Heavy Duty Industrial

Electroslag Remelting Mould Esr

Price 5000 USD ($)

Minimum Order Quantity : 1 Parcel

Application : Metallurgical industry, special steel and alloy production

Usage : Other, Used in Electroslag Remelting process for metal refining

Size : Customizable as per requirement

Rating : Industrial grade

Short Net

Price 5000 USD ($)

Minimum Order Quantity : 1 Set

Application : Multipurpose net for sports, boundary, animal enclosure, etc.

Usage : Other, Sports, Fishing, Protective barrier

Size : Customizable as per requirement

Rating : A grade